All published articles of this journal are available on ScienceDirect.

Effect of Bombyx Mori Silk Fiber Volumetric on Water Sorption of Fiber-reinforced Composite

Abstract

Background:

Dental resin is frequently reinforced with synthetic dental fibers like glass fiber. Dental glass fiber can be challenging to find and costly in Indonesia. Bombyx mori silk fiber is a robust, convenient, and reasonably priced natural fiber substitute. Bombyx mori silk fiber is commonly used in medicinal applications as a post-surgical suture.

Aim:

The aim of this study was to assess the volumetric effect of Bombyx mori silk fiber on the water sorption of fiber-reinforced composite (FRC).

Materials and Methods:

This study was an experimental laboratory. The materials used in this study were Bombyx mori silk fiber and flowable composite. Four groups of FRC samples were made using volumetric fibers at 0%, 5%, 10%, and 15% (n = 4). The test of water sorption was standardized (ISO 4049). The results were analyzed using one-way ANOVA (p<0.05).

Results:

The mean of water sorption of Bombyx mori silk fiber FRC for volumetric 0%, 5%, 10%, and 15% were: 0.475 ± 0.030%; 0.681 ± 0.033%; 0.889 ± 0.008%; 1.318 ± 0.039%, respectively. The present study showed that Bombyx mori silk fiber volumetric influenced the water sorption of FRC (p<0.05).

Conclusion:

The increased Bombyx mori silk fiber volumetric significantly increased the water sorption of FRC. The presence of a small gap caused by the weak interfacial bonds of the dental resin and fiber leads to water penetration.

1. INTRODUCTION

Fiber-reinforced composite (FRC) is a type of composite that comprises fibers as a reinforcer or composites containing fibers and resin matrix as a binder [1]. Additionally, it is stated that FRC is a substance that combines the mechanical and physical qualities of fiber and polymer [2]. Fiber-reinforced composite in dentistry allows for the presence of adhesive materials, aesthetic and non-metallic, for dental restorations, even in molar tooth cases [3]. Short fiber reinforced composite was developed as a dental composite for dentin replacement material. The mechanical properties of dental composites reinforced by short e-glass fiber fillers are higher than the composite resins with conventional fillers [4-6].

Dental glass fiber can be challenging to find and costly in Indonesia. The alternative of natural fiber that is strong, easy to obtain, and less expensive is Bombyx mori silk fiber. Silk fiber Bombyx mori is one of the natural fibers that can be an alternative to synthetic fiber [7]. The mechanical strength of the Bombyx mori silk fiber is comparable to the e-glass fiber [8]. One of Indonesia's provinces, Central Java, produces 2.15 tons of silk yarn annually [9].

Bombyx mori silkworm larva spins the cocoon that produces fiber [10]. This Silk fiber is mostly used in the textile sector [11]. In medical applications, silk fiber is used for medical sutures, scaffolds, and drug delivery material [12]. This fiber consists of 2 types of protein, namely sericin and fibroin [13]. Sericin is a water-soluble glycoprotein that binds fibroin, a water-insoluble protein of silk fiber [12]. The silk fiber Bombyx mori has the properties required for biomaterial applications, including biocompatibility, low toxicity, no irritation [14], and good mechanical properties [15].

When applied in the oral cavity, FRC is in a moist environment due to saliva and other liquids [16]. The exposure of restorative materials such as FRC by saliva affects water sorption [17]. Water exposure can cause the detrimental effect of breaking the fiber-polymer matrix bond, leading to decreased flexural strength due to the plasticization of the polymer matrix with water molecules [18, 19] and resulting in expansion of pressure, thus damaging the bond between the matrix and the fiber [20]. Volumetric fiber affected the bond between the matrix and fiber. The increased fiber volume provides better bonding and lower water sorption [21].

Bombyx mori silk fiber's mechanical characteristics and biocompatibility have made it more widely known that it can be used in medical applications [22]. However, it is less common to use silk fiber in dentistry [12]. Hence, the application of Bombyx mori silk fiber requires further investigation. This study aimed to evaluate the effect of Bombyx mori silk fiber volumetric on water sorption of fiber-reinforced composite. To the best of our knowledge, using Bombyx mori silk fiber as a bio-based dentin replacement has never been previously reported.

2. MATERIALS AND METHODS

This experimental laboratory study was conducted in an Integrated Study Laboratory at the University. The Ethics and Advocacy Unit of the Dentistry Faculty of Gadjah Mada University approved the study with No. 00917/KKEP/FKG-UGM/EC/2017.

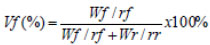

Bombyx mori silk fiber was obtained by boiling process (Fig. 1). The silk fiber was chopped to 1 mm. The fiber was kept in the desiccator for 24 hours. The short fibers (Fig. 2) [24] measured the weight according to the volumetric fraction of the silk fiber Bombyx mori 5%, 10%, and 15% using a precision digital scale of 0,0001g. The total FRC samples in this study were 16 samples. Four groups of FRC samples were made using volumetric fibers at 0%, 5%, 10%, and 15% (n = 4). The volume volumetric fraction was calculated by transforming the volume percent to weight using the following formula [23].

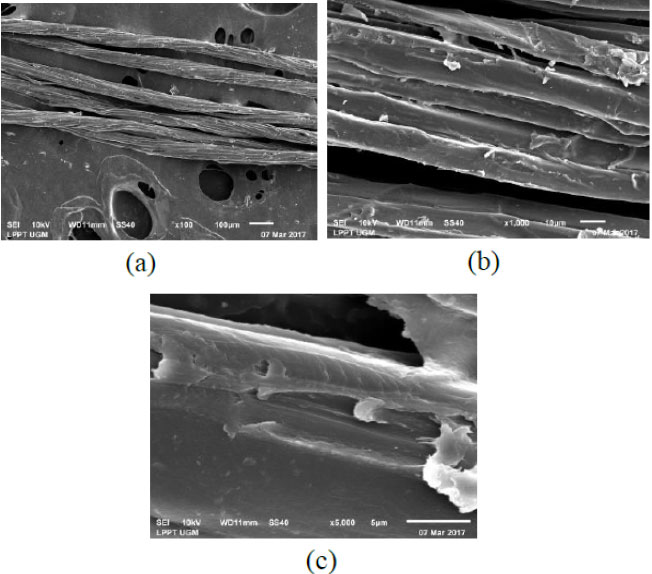

|

Annotation:

Vf(%) = volumetric of silk fiber Bombyx mori (%)

Wf = weight of silk fiber Bombyx mori (g)

rf = density of silk fiber Bombyx mori (g/cm3)

Wr = weight of resin matrix without fiber(g)

rr = density of resin matrix (g/cm3)

The metal mold 25x2x2 mm3 in size (Fig. 3) was marked at a height of 0.5 mm for placing of resin and fiber, then placed on the glass plate. The flowable composite was injected into the mold until it was filled entirely in sample group 0% fiber. The fiber-added group obtained injections up to the marker limit (0.5 mm) [24, 25]. The mold began to be filled with a flowable composite and fiber mixture, and it was then continuously injected with resin until the mold was fully filled. A celluloid strip was used to shield the FRC surface before a light curing device irradiated the top and bottom portions of the sample perpendicular to the sample. After the sample had finished being irradiated, the leftover material was polished with 1000-grit abrasive paper (ISO 4049) [26]. The sample was cleaned using tissue and weighed with a precision digital scale of 0.0001 g before immersion.

The conical tube was used to place the sample in 20 ml of aquades. Each sample was immersed in aquades and kept for seven days at 37°C in an incubator (ISO 4049) [26]. The sample was taken out of the conical tube, dried with a tissue for ten seconds, and then allowed to air dry for fifteen seconds. Then, the sample was weighted after immersion using a precision digital scale of 0.0001 g to calculate water sorption. Water sorption was calculated using the formula [27]:

Weight changes(%) = (W1 – W2) / W2 x 100 (%)

Annotation:

W1= the sample weight after immersion (μg)

W2= the sample weight before immersion (weight in dry condition) (μg)

The water sorption data were analyzed statistically by performing a normality test using the Shapiro Wilk and homogenity test of Levene's tests. Furthermore, a parametric analysis was conducted using one-way ANOVA to see the effect of volumetric variation of silk fiber Bombyx mori on the water sorption of fiber-reinforced composite, with a significance level of p<0,05. After that was proceeded with the LSD post hoc test to see the magnitude of the average difference between each group. The scanning electron microscopy (SEM) test was performed after a study to examine the interfacial bonds between the Bombyx mori silk fiber and the composite resin.

3. RESULTS

The results of the effect of volumetric silk fiber Bombyx mori on fiber-reinforced composite water sorption are shown in Table 1.

| FRC Group | n | Mean (%) | Standard Deviation | p |

|---|---|---|---|---|

| Composites Fiber 0% | 4 | 0.475 | 0.030 | 0,000 |

| Fiber 5% | 4 | 0.681 | 0.033 | |

| Fiber 10% | 4 | 0.889 | 0.008 | |

| Fiber 15% | 4 | 1.318 | 0.039 |

Table 1 demonstrates the lowest water sorption rate in the FRC fiber group, 0%, and the highest in the 15% FRC fiber group. In general, all FRC groups with various volumetrics tended to improve water sorption. The data were statistically analyzed by normality test using the Shapiro-Wilk test. Considering that all groups' water sorption data passed the Shapiro-Wilk normality test with a statistical value of p> 0.05, it was determined that the data were normally distributed. Levene's test was used to run the homogeneity test, and the outcome revealed a statistical value of 1.879 (p=0.187) with a p-value of 0.05. Therefore, we concluded that the data were homogen. Furthermore, the data were analyzed using one-way ANOVA. The results showed the value F=580,340 (p<0,05). The data suggest that volumetric fiber significantly influences the water sorption of FRC.

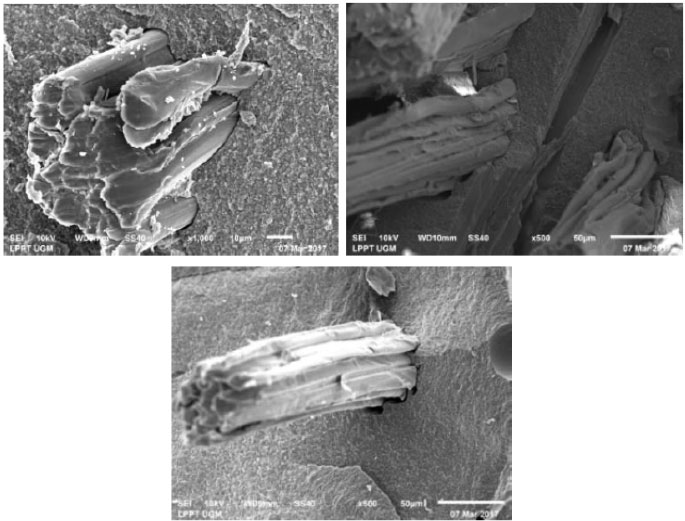

The findings were subsequently examined using the LSD post hoc test. The result of post hoc LSD analysis (Table 2) on FRC water sorption with various fiber volumetric showed a significant difference in all groups (p<0.05). The findings of the scanning electron micrographs (SEM) tests revealed a 6–8 μm void between the composites and the fiber (Fig. 4).

3. DISCUSSION

The results demonstrated that there were differences in FRC water sorption with various fiber volumetrics. Table 1 shows the increasing tendency of water sorption in all FRC groups. This result is similar to the study of Dhakal et al. (2006), indicating that the water sorption increased by raising the fiber volume fraction because there was an empty gap between the composites and the fiber [28].

The samples containing fibers had higher water sorption compared to groups without fiber. Increasing Bombyx mori silk fiber volumetric increased water sorption of FRC. This may be due to the amphiphilic Bombyx mori protein molecule, which has a combination of hydrophobic (fibroin) and hydrophilic (sericin) [29]. Fibroin is insoluble in water. Sericin is a water-soluble protein [12].

In this study, silk fiber Bombyx mori was boiled in a boiling machine for 15 minutes at 80°C [9]. One step in the degumming process is boiling. Degumming is the method for getting rid of sericin [30]. Degumming can affect the mechanical properties of the Bombyx mori silk fiber due to changes in the microstructure of the fibroin core and the bonds between them [31]. There was no fiber surface modification in this study. The boiling method cannot completely remove sericin [32, 33]. Consequently, there is still sericin present on the fiber core's surface [34].

Three different mechanisms can explain the diffusion of water in FRC. The first occurrence is the diffusion of water molecules into the micro gap between the polymer chains. The second involves capillary transport into the cracks, thus weakening the bond between the fiber and the composites. The third involves the transport of micro cracks on the matrix occurring during the FRC manufacturing process [35-37]. Hydrophilic sericin blocks the bond between the matrix and the fibers, causing a poor bond between the composite resin and fiber [37]. The water sorption of FRC will continue from the composite resin to the fiber. Sericin, which is hydrophilic with an amorphous structure and slightly β-sheet, causes the water to penetrate easily [38]. After conducting a study to examine the bindings between the silk fiber and the resin matrix, the scanning electron microscopy (SEM) test was conducted. The results of the SEM test revealed a 6 to 8 μm void between the resin matrix and the silk fiber.

Post hoc LSD analysis (Table 2) of water sorption showed significant differences in each sample group. This was due to the volumetric difference of silk fiber in the composite resin. Sericin contained in the surface of silk fiber resulted in the hydrophilic nature of silk fiber, which resulted in high water sorption. By increasing the volumetric silk fiber from 0%, 5%, and 10% to 15%, the number of sericin in FRC was increased, and the bond between the composites and the fiber was weak, so the water sorption increased.

| FRC Group | Composites Fiber 0% | Fiber 5% | Fiber 10% | Fiber 15% |

|---|---|---|---|---|

| Composites Fiber 0% | -0.206* | -0.414* | -0.843* | |

| Fiber 5% | - | -0.208* | -0.637* | |

| Fiber 10% | - | - | -0.429* | |

| Fiber 15% | - | - | - |

A restorative material is considered to have met the initial requirements if the water sorption of the test sample is ≤ 40 µg/mm3 [26]. In this study, the lowest water sorption mean in the composites fiber 0% group was 0.475%, equivalent to 9 µg/mm3, and the highest in FRC fiber 15% group was 1.318%, equivalent to 23 µg/mm3. Compared with short FRC containing glass fiber, the water sorption mean was 0,308%, equivalent to 7 µg/mm3. It can be concluded that the water absorption test results of all FRC groups remained below the allowed threshold for dental filling materials or dentin replacement. However, when compared to short FRC containing glass fiber, the water absorption of silk fiber FRC was higher.

The limitation of this study was that the process of mixing silk fiber with composites still uses the manual method. Silane coupling agent has not been added in the mixing of silk fiber reinforced composite, which may be one of the causes of poor interfacial bonding and the formation of voids.

CONCLUSION

In conclusion, this study demonstrated the potential application of Bombyx mori silk fiber as a dentin replacement. We showed that increased volumetric silk fiber Bombyx mori increased the water sorption of FRC as there is a small gap due to weak interfacial bonds between the composite resin and fiber so that water penetrates more easily. By preparing the Bombyx mori silk fiber to be more hydrophobic and using coupling agents, silk fiber can be potentially used as an alternative in the manufacture of fiber-reinforced composites in dental applications.

LIST OF ABBREVIATIONS

| FRC | = Fiber-reinforced Composite |

| SEM | = Scanning Electron Micrographs |

ETHICS APPROVAL AND CONSENT TO PARTICIPATE

The ethics was approved by the Ethics and Advocacy Unit of the Dentistry Faculty of Gadjah Mada University with No. 00917/KKEP/FKG-UGM/EC/2017.

AVAILABILITY OF DATA AND MATERIALS

The data supporting the findings of the article is available in the repo.unand.ac.id at: http://repo.unand.ac.id/50842/

FUNDING

This research was partially supported by Universitas Gadjah Mada, grant number 048/Lab Riset/IV/2017.

CONFLICT OF INTEREST

The authors declare that there is no conflict of interest regarding the publication of this paper.

ACKNOWLEDGEMENTS

The Faculty of Dentistry and the Department of Mechanical and Industrial Engineering, Faculty of Engineering, Universitas Gadjah Mada, Yogyakarta, for providing facilities to support this research.