All published articles of this journal are available on ScienceDirect.

Conventional Border Molding versus Digital Impression on Complete Denture Impression: A Review

Abstract

Background:

Definitive working impression of a complete denture requires proper border molding as part of impression techniques to capture the essential details of anatomical landmarks and the functional sulcus. In the era of digital dentistry, the digital impression using optical scanners may be an alternative to conventional techniques.

Objective:

This paper discusses the differences between conventional methods and digital impression in a complete denture covering its procedures, importance and relevance of border molding in both methods for a good working impression.

Methods:

The study reviewed papers from 2000 to 2022 in Medline and PubMed on border molding and complete denture working impression. Both methods were revised and contrasted to discuss the relevance and advantages of both approaches.

Results:

It is still controversial to conclude that digital impression is superior to the conventional method. Both methods have the strength to improve the quality of the impression taking procedure and complete denture quality of retention and stability. Digital impression gives more comfort and less post insertion adjustment. The conventional method still has good clinical outcomes in terms of retention and stability. Border molding should not be disregarded as part of the working impression procedure.

Conclusion:

The paper concludes that border molding and the conventional working impression technique are still relevant due to their comparable outcome compared to digital impression, as less cost and high skills are involved.

1. INTRODUCTION

One of the various factors contributing to the quality of complete denture is the impression techniques and materials used [1]. A good practice of impression techniques will reproduce accurate oral function. This can be achieved by using different types of material to capture the functional width and depth of sulcus for an excellent border seal during the border molding procedure. Border molding is part of the impression technique during complete denture construction, shaping soft material along the impression tray borders to copy the shape, contour, and size of the vestibules [2]. This process is essential for intimate contact between the denture borders with the adjacent vestibular tissue and maintain the denture border seal during rest or functional activity.

The low fusing tracing stick impression compound type, also called Green stick, was originally used for border molding. It was introduced by the Green brothers in 1907, and step-by-step molding needs to be done within different small sections on a special tray to capture the shape of vestibules [3, 4]. This method can be quite tedious and messy, and takes a long time to complete. The conventional method has improved to single-stage technique by using easy handling and more dimensionally stable materials such as polyether, vinyl polysiloxane (VPS) impression material, or condensation silicone (c-silicone) [5, 6].

Recently, digital impression has become a better option for some clinicians, but it may omit the relevance of border molding and thus may compromise the retention and stability of the complete denture. This paper describes the relevance of conventional border molding during impression taking and the advantages of the new digital impressions in recent times.

2. IMPORTANCE OF BORDER MOLDING FOR DEFINITIVE IMPRESSION TAKING

The intimate contact of denture borders with the supporting soft tissue creates an excellent peripheral seal; good denture base adaptation will produce good retention for the denture. Penetration of air between this intimate contact will be prevented during denture function [7] through the application of border molding before impression taking. Several studies showed an increase of up to 53.2% in denture retention if border molding is applied, which emphasizes its importance [5, 8].

Border molding procedure during the definitive impression of a complete denture was introduced in the years 1900 to 1929 with various methods [3]. One method was by sucking or swallowing movements and by moving actions of the peripheral musculature in order to form the height and width of the mucobuccal fold of the denture border [3]. Border molding was recommended as it was considered a biological necessity of muscle function to obtain denture retention. By obtaining a correct extension of the denture border by border molding, the definitive impression can be prevented from overextension, while creating good peripheral musculature or mucobuccal folds and denture seal to the soft tissue for the best denture retention.

Prior to accurate border molding and definitive impression, a rigid and dimensionally stable special tray has to be prepared, which is commonly fabricated using cold cure or light cure acrylic resin for tray material. This is followed by a correct selection of impression material for the definitive impression. Selection of impression material mainly considers the condition of residual ridge and mucosa. Zinc oxide, eugenol, or alginate are the common materials used to capture adequate height and width of the residual ridge, while polyvinylsiloxane, polysulfide, and polyether are preferred for severely resorbed or flat residual ridge [8-10]. Notably, a patient’s mucosal condition, such as hyposalivation or dry mouth, is contraindicated to use zinc oxide eugenol for definitive impression material due to its reaction to the mucosa, and the impression may be difficult to remove.

The other main concern is that of the dentist’s knowledge and understanding of the fundamentals and ideas of impression making. It is imperative for the dentist to know the entire landmarks of the denture bearing area needed for each case and the handling technique of the impression materials [8, 9, 11]. The space needed for border molding material to gain the correct peripheral and posterior seal will influence denture retention. The material used for the conventional method of border molding should be exactly enough to capture the functional sulcus and it will be part of the definitive impression detail. The definitive impression should not be covered with the border moulded border of the denture extension so as to confirm the best denture extension and retention.

Border molding is carried out through a few techniques and materials. Studies showed 64% to 95% of dentists, prosthodontists, or even dental school educators preferred Green stick compounds, while less than 10% used other materials such as putty or heavy-body elastomer and polyether [8, 10]. The conventional border molding method is performed by capturing the vestibular fold (functional sulcus) step by step in small sections, and studies reported of an average of 17 placements were required to obtain a definitive maxillary impression of one patient [2, 4]. It is accomplished with the dentist moving the tissues in a manner consistent with function [12]. Using Green stick compound as the material allows easy manipulation, needs less skill, and is cheap. It forms a well-defined and smooth surface for border molding, as well as being convenient for patients. Little or no history of patient allergies towards Green stick compound has been reported [13].

However, border molding using Green stick compound would be time-consuming, tedious, and discomfort for the patient when the tray borders have to be molded in steps in separate section-by-section applications of the mucobuccal fold area [4]. Besides, Green stick compound has a short manipulation time, which may provide insufficient time for an inexperienced clinician to perform movement and capture accurate vestibular tissue on the periphery of the special tray [4, 9]. The clinician must heat the compound at the correct temperature to soften without burning it, before applying it to the impression tray. Then, the tray has to be tempered to prevent discomfort during tray placement into the patient’s mouth [12]. Precaution needs to be taken with the heated Green stick compound as it has to be softened enough to be molded and, at the same time, will not cause injury to the patient’s mucosa.

The various methods of border molding have been compared. The effectiveness of border molding was measured by denture retention and impression making, as well as the impression materials used. Some studies concluded that sectional border molding was better than single-step border molding [4, 5, 14]. In contrast, other studies concluded that single-step border molding showed better retentive values than the sectional border molding technique [9, 12, 15]. Despite the contradicting conclusions, the dentist’s skills, experience, ability to choose the material, and careful performing of the techniques of border molding are important factors for the success of denture retention.

3. SINGLE-STEP AND TWO-STEP BORDER MOLDING IN DEFINITIVE IMPRESSION TECHNIQUE

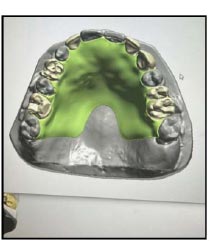

In relation to single-step border molding technique, the use of poly vinylsiloxane and polyether impression material for border molding is increasing [16]. Single-step border molding is when the border molding and impression taking are performed at the same time using one material – commonly poly vinylsiloxane or polysulfide (Fig. 1). Others may practice a single step border molding by using poly vinylsiloxane or polyether, then followed by impression taking using heavy-body silicone [2, 3]. The definitive impression procedure is getting easier, less time-consuming, and improves the patient’s comfort.

Compared to Green sticks, the materials have better dimensional stability and less incidence of mucosal injury from overheated Green stick compound. Nevertheless, the pressure would be similar at all areas of the mucobuccal fold, forming a better border molding, extension of the functional vestibular, and attachment for the denture flange [1, 3, 5]. Besides, special equipment or instrument is needed to dispense the impression material, such as the automix machine for polyether or gun impression material dispenser for poly vinylsiloxane.

Irreversible hydrocolloid impression has been used for the definitive impression as clinicians realize it significantly time-saving due to the definitive impression made immediately [17]. Unfortunately, this material generally results in poor denture fitting and adaptation. This caused extensive modification during denture insertion due to overextension and mucodisplacement of the impression, especially when no border molding was done. As a result, most studies would not recommend irreversible hydrocolloids as the material for definitive impression [17].

Several studies have shown that single-step border molding helps to encounter the drawbacks of the conventional techniques, especially in reducing the procedural time, but most reported that there is no significant difference in terms of denture retention [4, 14, 15] and adjustment during and post-insertion visit [17]. Due to these findings, the two-step impression technique or conventional method of border molding – with Green stick for functional border molding and zinc oxide eugenol or polysulfide polymer as the definitive impression material – still remains as the gold standard for complete dentures definitive impression [8].

4. DIGITAL IMPRESSION OF COMPLETE DENTURE AS ALTERNATIVE TO CONVENTIONAL IMPRESSION TAKING

Digital impression has been introduced since the 1980s, and its use is increasing till now with better and more sophisticated software systems [18]. In digital impression, an intraoral scanner is used to directly capture the required intraoral area of hard and soft tissues for the dentures. The acquired information is then generated by CAD-design software to form a virtual working model (Fig. 2). Through the digital CAD-design software, the denture was then fabricated via 3D printing or milling. The fabrication process includes the construction of special trays, baseplate and wax rims, trial plates for tooth setting assessment, and finally, the definitive dentures. Several workflows were reported on different methods performed by the dentist’s preference, which showed no significant difference in accuracy, denture retention, and patient’s satisfaction [18-22].

Digital impressions may also be produced through extraoral scanners by scanning the working models produced from conventional impression-making. This method does not eliminate most of the conventional procedures in the denture construction process. It aims to simplify the tooth set-up procedure and denture try-in using teeth setting software for dentures [20, 22]. However, the possibility of distortion or dimensional changes in denture construction may occur possibly during the combination of conventional impression taking with scanning the working models prior to the tooth setting stage.

The workflow and protocol of the digital complete denture procedure differed between different types of digital or CAD/CAM systems. Clinicians have to choose the protocol according to the system used and their own preferences [20]. Method of scanning, either by intraoral or extraoral scanner, are similar even for a different system; however, the number of visits or length of the visit will be slightly varied between two to three visits for the denture to be ready for insertion. While this has decreased clinical chair time, the procedures involved with complete denture impressions have remained unchanged [20, 21]. The elimination of conventional impression techniques in digitally fabricated dentures offers more benefits in increasing patient comfort, reduction of dimensional changes of the impression, disregarding the need for custom trays, reducing or removing the use of the impression materials, and potential cost- and time effectiveness [21, 22].

In the digital impression technique, it was suggested to practice mucostatic impression rather than the functional impression, especially on a thin and sharp or flabby ridge [22]. These unfavourable ridges have a difference in mucosa resilience, causing difficulty in capturing the viscoelastic soft tissues during intraoral scanning of edentulous patients, thus creating a lack of denture accuracy [22-24]. As border molding and palatal seal were not required, the digital impression maximizes the surface tension by creating an intimate contact between the denture fitting surface and underlying mucosa [22, 24]. Digital impression captures excellent soft tissue and hard tissue in great detail, thus improving denture adaptability and overall retention. Even though the digital denture tends to have an underextended denture flanges due to the mucostatic impression, a slight under extension will not affect the retention and stability yet results in no trauma for overextension [22, 24]. In addition, post-insertion visit showed less presence of ulceration and many more other issues [22].

A few advantages of digital impression are considering the use of the scanning device without investing in the cost of impression material and the fabrication of special trays. Apart from this, the scanning device has the ability to patch any missing area on the initial impression by rescanning the required area in just a few seconds and it is more convenient for patient and clinician [20]. This would be a preference for patients with gag reflexes and disability. It was suggested for clinicians understand and learn the process of a digital denture and the use of a variety of available software [18, 20, 21]. Digital impression is practical and easy to manipulate. It does not require expertise to achieve the same level of proficiency as the conventional impression [20].

Despite the few advantages, the drawback of digital impression is the inaccuracy of the software to capture and process the digital data and transform the impression into a virtual study model, as reported by Goodacre [21]. Goodacre suggested the use of tissue additives, such as pressure indicating paste (PIP) and composite resin markers, to improve the scanning result, which can improve the ability of the scanner [21]. In addition, from the current observation, the technology of artificial intelligence in software has rapid advancement over the years, and the scanner performance would be much improved.

5. RELEVANCE OF CONVENTIONAL BORDER MOLDING IMPRESSION MAKING METHODS AND DIGITAL IMPRESSION

Similar number of visits and post-insertion adjustment was reported when two techniques of impression with conventional border molding and a modified technique using impression compound followed by heavy-body poly vinylsiloxane impression materials were compared [25]. Another simpler method using alginate and stock tray versus the conventional method showed no significant difference in terms of patient satisfaction and clinical outcome on the denture’s function and retention [26]. In addition, Carlsson et al. reported that two-step procedure was not essential and superior to the one-step method [25]. Therefore, conventional border molding seemed to be no longer relevant except in certain clinical situations that requires special technique. To the extent of our knowledge, reporting on unfavourable ridges using digital scanning is yet to be published.

Most textbooks taught border molding as an important part of making definitive impressions for complete dentures. However, many procedures, including border molding, lack support of good evidence on the effect of clinical outcomes on its retention and occlusal force at dislodgment [24, 26, 27]. The study even concluded that border molding has been overestimated in the literature due to the fact that if the border molding protocols are followed or not [25].

The best practice of conventional impression for complete denture procedure is the construction of special trays after the primary impression, then border molding, before the definitive impression can be made. Several studies have suggested simpler techniques by single-step border molding or even without the practice of border molding [2-5, 12, 15], including the digital impression making [18, 21-24]. However, there was either a slight significant or no significant difference in the patients’ and dentists’ preferences [20, 23, 24].

The elimination of certain stages in complete denture construction such as tray selection, impression material handling, packaging and shipping, and laboratory procedures such as model trimming has brought digital impression as the preferred method nowadays and cost-effective in the long run [27]. Although the high cost to set up digital practice and impression scanning may lag the impression procedure, it was reported that the duration was faster than remaking the entire impression conventionally [18, 27, 28]. On the other hand, it depends on the clinician’s experience with the system itself which may influence the digital impression making time, thus whereby the experienced clinician may produce a better impression and in a less time [18].

Jung reported there was no significant difference in the mean area of displacement on the edentulous supporting areas when comparing the conventional impression made with a simple modified close-mouth impression with the digital impression method [29]. The greatest difference was seen in the mandibular vestibule. This finding was in agreement with a review paper that reported that impression accuracy is superior, but there were no statistically significant differences [30]. It can be concluded that digital impressions may have similar accuracy compared to conventional methods.

Table 1.

| Features | Conventional Border Molding Method | Digital Scanner for Border Molding in Impression Taking |

|---|---|---|

| Material used | • Border molding is mainly used impression compound (e.g.: green stick) or single step using poly vinylsiloxane or polyether apart from the need of special tray made from acrylic type material [8-10, 25, 26]. | • Relatively maybe more expensive for first set up for the scanner and cad-design software. However, it may be more cost-effective as it does not need impression and special tray material [20-22]. |

| Chair time duration | • May reduce for single step border molding but may increase time for sectional method of border molding [2, 4, 17]. | • Reduced chair time as compared to conventional especially if the conventional needs repetition [20, 21]. |

| Accuracy of the impression | No significant [29] or similar accuracy [30] compared between conventional and digital impressions. | |

| Denture retention | • No significant difference of retention as compared to digital impression denture [24, 26, 27]. • 53.2% increasein denture retention with border molding done during impression [5, 8]. • Sectional method of border molding is better than single step border molding [4, 14, 15]. |

• No significant difference compared to conventional impression method with border molding [18]. • Satisfactory retention [22]. |

| Post insertion adjustment | • No significant difference. Depends on the material used and the clinician's skills during impression taking [17]. | • Less post insertion denture adjustment due to mainly it being underextended [22, 30]. |

Following the evaluation of edentulous patient preference on digital workflow and conventional methods, a study by Bidra et al. [19] reported favorable visual analogue scale evaluation in one year for phonetics (93%), lip support (94.3%), mastication efficiency (91.5%), aesthetics (94.8%), and overall denture satisfaction (92.8%). Minor or no adjustments within 24 hours were needed with the digital protocol, as approximately 85% to 87% of patients required adjustment with conventional methods [22, 30]. This may be due to the underextended dentures commonly constructed by digital denture [22-24]. However, the retention was reported as satisfactory [22].

Although border molding and definitive impression techniques are important in fabricating successful complete dentures, it is unlikely that the need for post insertion adjustment was rooted from border molding. Indeed, border molding is still relevant to be taught in dental schools as a basic fundamental technique for good impression making since it showed good clinical outcome and cost saving [26, 31] (Table 1).

CONCLUSION

It is still controversial to conclude that digital impression is superior to the conventional method. Evidence showed that digital impressions can give more comfort, better clinical outcomes, and less post-insertion adjustment than the conventional method. However, the conventional method still has good clinical outcomes in terms of retention and stability and should not be disregarded particularly border molding. With the feasibility of digital, border, molding is still relevant, especially in dental schools.

LIST OF ABBREVIATIONS

| VPS | = Vinyl polysiloxane |

| c-silicone | = Condensation silicone |

CONSENT FOR PUBLICATION

Not applicable.

FUNDING

This article was funded by Universiti Sains Islam Malaysia, grant code PPP/GPI/FPG/051014/60319.