All published articles of this journal are available on ScienceDirect.

Comparative Study of Adhesion of Brackets with Metal Injection Molding (MIM) Technology and Welded bases: In vitro Study

Abstract

Introduction:

Brackets bonded to enamel surface depend on the adhesion material and the quality of the bracket base.

Objective:

The aim of this study was to compare the shear bond strength of metallic brackets with Metal Injection Molding (MIM) technology base or welded base.

Materials and Methods:

Forty mandibular extracted premolars mounted in acrylic resin blocks were divided randomly into two groups, both bonded with Transbond XT. In Group 1, brackets with MIM technology bases (Masel) were used, and in group 2, brackets with a welded base (Morelli) were used. After 24 hours, all brackets were tested for shear bond strength in a universal testing machine. Intergroup comparison was performed with an independent t test.

Results:

MIM base brackets showed a mean maximum load registered of 107.55 N, a mean shear bond strength of 9.58 MPa with a standard deviation of 5.80 MPa and the welded base brackets showed a mean maximum load of 167.37 N, a mean shear bond strength of 13.28 MPa with a standard deviation of 2.58 MPa. The difference between the two groups was statistically significant, indicating a higher shear bond strength of the welded base brackets.

Conclusion:

It was concluded that the brackets with welded bases presented a significantly higher shear bond strength than the brackets with MIM bases.

1. INTRODUCTION

Dental enamel is one of the strongest structures in the human body, composed of various minerals that provide it with hardness and elastic properties, making it resistant to wear and fractures while being friable [1].

Since the introduction of phosphoric acid in dentistry, long-term effects have been achieved for bonding orthodontic appliances to the enamel surface of the teeth allowing for increased adhesion force between the enamel surface and the bonding system, and providing mechanical imbrication of the resin and microporosities produced by the acid treatment of the enamel surface [2].

Thus, bracket bonding improved and minimized the replacement of orthodontic fixtures, achieving a significant improvement in orthodontic therapy [3]. Similarly, a variety of adhesive systems and different brackets have been developed for direct bonding with various base types to improve adhesive imbrication between the tooth and orthodontic accessories [4-8].

Failure of bracket bonding during the course of orthodontic therapy is not an uncommon occurrence [9], therefore, the bracket bases have been modified to improve the anatomy and to achieve better mechanical retention by perforations, meshes, grooves, spherical designs, and different metal particles [7].

Several authors have suggested that the microscopic characteristics of the bracket base, particularly the mesh designs, may increase or decrease the effectiveness of mechanical interlocking with the adhesive. These features include rough or smooth mesh wires, mesh size, wire diameter, weld points, the integrity of the enamel surface, the conditioning procedure, and the type of adhesive system used [10-12].

Several researches have been conducted to determine the in vitro adhesion forces for each type of metal bracket base [6, 7, 13-15], other factors highlighted and the weld between the base and the metal mesh reducing the available retention surface, which can be significant in view of the tendency to reduce bracket base sizes [4, 8, 10, 13-16].

Among the main methods of manufacture of metal brackets are: casting, molding, and injection. A wide range of methods have been employed for the manufacture of orthodontic accessories, including a various kinds of metals and stainless-steel alloys [17].

The objective of this study is to compare the shear bond strength of metal brackets with metal injection molding (MIM) technology or welded bases. The tested null hypothesis was that there is no difference in the shear bond strength of metal brackets with metal injection molding (MIM) technology and welded bases.

2. MATERIALS AND METHODS

In order to establish the number of specimens required to indicate statistical significance, between the experimental conditions, a pilot test with 10 specimens with a minimum difference of 3.18 MPa, an alpha error of 5% and a beta error of 20%, indicated that 40 teeth were needed this research, 20 in each group.

Inclusion criteria for the selected teeth were: first premolars extracted for orthodontic purposes; absence of fractures caused by forceps; absence of caries lesions and absence of restorations. All teeth were examined with 10x magnification. The premolars used in this study were donated by educational institutions.

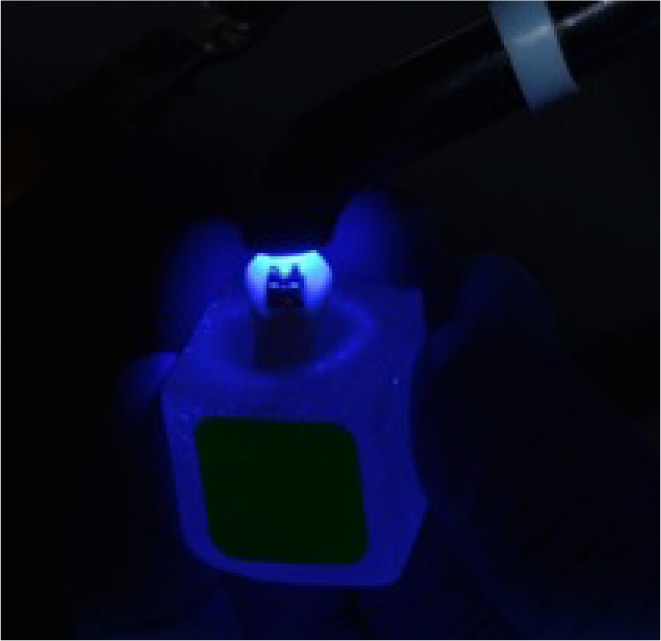

For the 40-specimen preparation, a prophylaxis with pumice paste (without fluoride) was performed with a Robson brush on the buccal surfaces of the teeth. The teeth were inserted in blocks of acrylic resin (20mm x 20mm) until the cement-enamel junction, leaving the crown fully exposed (Fig. 1). The bonding procedures of both groups started with acid conditioning with 37% phosphoric acid for 30 seconds [6, 18] and shortly thereafter, were rinsed with abundant water jet and dried with an oil and a water-free air source.

Soon after, the teeth were randomly divided into two groups of 20 teeth, and two types of brackets were bonded.

Group 1: 20 MIM (metal injection molding) technology stainless steel brackets for first mandibular premolars (Roth 0.022” x 0.028”, Masel Enterprise, Bistrol, USA).

Group 2: 20 welded bases stainless steel orthodontic brackets for first mandibular premolars (Roth 0.022” x 0.028”, Morelli, Sorocaba, Brazil).

Brackets of both groups had the same linear area of their bases of 12.5 mm2.

The adhesive system used was Transbond XT (3M, Unitek, Monrovia, USA). A thin layer of the primer was applied for 10 seconds and light-cured for 30 seconds with an 1800 mW Woodpecker Led-F light curing light, wavelength 420-480 mm2. After a uniform layer of the resin was applied to the base of the brackets, and were positioned in the center of the clinical crown exerting pressure toward the tooth, excess of resin was removed from the bracket margins and light-cured for 60 seconds (Fig. 2). All specimens were prepared and brackets were bonded by the same operator (L.A.V.I).

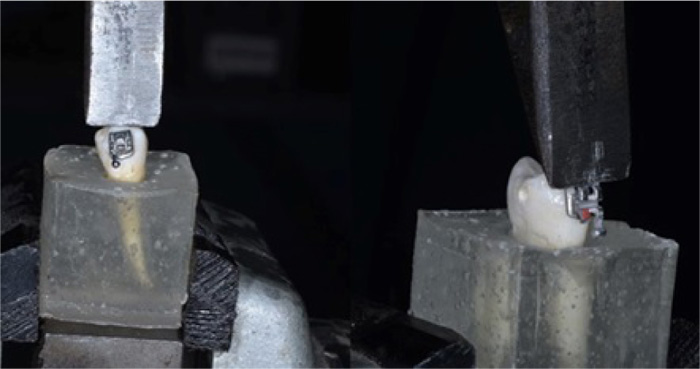

After 48 hours of bracket bonding, they were placed in a device fixed to the bottom base of an automated Universal Testing Machine (Tinius Olsen Super L120 1980 Testing Machine, Houston, USA) (Fig. 3), which performed shear strength testing at a speed of 0.5 mm per minute.

The tooth blocks were held in an upright position, and a beveled stainless-steel tip 1mm high and having a 10mm wide active edge was attached to the load cell #2 of the testing machine, positioned and rested on the resin plateau to test the bonding interphase between the bracket base and the resin (Fig. 4). The machine was then driven at a speed of 0.5 mm per minute in the direction of compression, thus developing a shear stress at the bracket-resin interphase until the fracture or rupture of the adhesive union. The values were recorded directly in kgf/cm2 on the digital monitor of the testing machine.

The shear bond strength was measured in Megapascals (MPa) and the maximum load registered was measured in Newtons (N).

2.1. Statistical Analysis

The normality of the data was checked with Shapiro-Wilk test. Data presented normal distribution and then parametric tests were applied.

Intergroup comparisons of the shear bond strength and maximum load registered were performed with independent t-tests. The level of significance was 5% (P<0.05). All statistical analyses were performed with SPSS version 22 for Windows (SPSS Inc., Chicago, IL, USA).

3. RESULTS

The shear bond strength of MIM base brackets had a maximum shear bond strength of 24.43 MPa and a minimum strength of 3.22 MPa, an average of 9.58 MPa, and a standard deviation of 5.80 MPa, with a maximum load registered of 274.13 N and a minimum load of 17.70 N.

The strength of the welded base brackets had a maximum shear bond strength of 20.18 MPa and a minimum strength of 9.72 MPa, an average of 13.28 MPa and a standard deviation of 2.58 MPa, with a maximum load registered of 222.11 N and a minimum load of 160.99 N. When the two groups were compared, there was a statistically significant difference in the shear bond strength and in the maximum load registered, indicating that the welded brackets presented a significantly higher shear bond strength and maximum load registered than the MIM base brackets (Table 1, Figs. 5 and 6).

| Variables |

GROUP 1 MIM BASE BRACKETS N=20 |

GROUP 2 WELDED BASE BRACKETS N=20 |

P | ||

|---|---|---|---|---|---|

| Mean | s.d. | Mean | s.d. | ||

| Shear bond strength (MPa) | 9.58 | 5.80 | 13.28 | 2.58 | 0.013* |

| Maximum load registered (N) | 107.54 | 65.11 | 167.38 | 32.55 | 0.000* |

4. DISCUSSION

Aiming at improving the adhesion strength of the materials, various bracket bases with different designs were developed, trying to improve the interaction of the materials and the enamel structure, and introduce modifications in the base designs, including base screen [10-12, 19-21], grooves [11, 22], or circular or rectangular perforated design bases [8, 10, 22].

The purpose of this study was to compare the bond strength of two types of bracket bases, using brackets with a mesh base and base injected in human teeth, as was also done in other studies [5, 10-12, 14, 20, 21, 23, 24]. Some studies used recently extracted bovine teeth [4, 7, 13, 25], which is well accepted in the literature due to the similar behavior of both enamel surfaces [13, 26, 27].

The methodology of the present study was standardized; the specimens were well adapted to the universal testing machine used; torques of the brackets were similar; the pressure during bracket positioning was standardized, so that the adhesive thickness was thin and uniform and adhesive excesses were removed without displacing the bracket [28, 29]

The strength of direct bonding orthodontic accessories is provided by several factors such as the design of the bracket base, the quality and type of substrate to be bonded on, enamel surface contaminants, and the adhesive system used [12, 30]. Among these variables, the adhesive system used in this research was Transbond XT adhesive system (primer and resin)(3M Unitek, Monrovia, USA), considered as the gold standard adhesion system [31, 32].

The shear tests were performed in the occlusal-gingival direction due to the larger mesiodistal dimension of the bracket in relation to the occlusal-gingival dimension, as performed in other studies [3, 23, 24, 33], offering better resistance to its removal when force is applied in this direction, and also standardizing the methodology employed.

Profit [34] reports that the maximum force during chewing by a child with a normal height between 6 and 11 years old is 5.01 kg and in adults, it is 13.5 Kg, these results are similar to other studies [35, 36]. Thus, it would be reasonable to infer, from these studies, that the release forces of brackets can vary from 5 to 13 kg. The results found in the present research demonstrate that using standardized bonding protocols and adhesive techniques, it was observed that the adhesion strength of the welded base brackets presented an average shear bond strength of 13.28 MPa (13.54 Kg) when compared to the MIM technology base brackets with 9.58 MPa (9.76 Kg), and this difference was statistically significant (Table 1). This difference is possibly attributed to the design of the bracket base that has a larger mesh spacing allowing more air to escape and better resin penetration, resulting in greater adhesion strength, as also reported in other researches [12, 37].

Molina et al. [38] compared the shear bond strength of MIM technology brackets with two types of meshes, conventional or rail-shaped and found no difference in shear bond strength, with values close to ours for the MIM conventional mesh base brackets.

Wang et al. [37] tested several welded mesh-based brackets with different base sizes and found that the brackets with the larger mesh size produced greater bond strength than the brackets with smaller mesh sizes. In the present study, both brackets tested presented the same size of the bases.

The amount of resin that remained in the enamel surface was not compared between the groups in the present study, but most of the resin remained in the tooth surface after the shear test. For bracket debonding it is preferable that the bracket/adhesive interface is predominant, leaving much of the remaining resin adhered to the tooth enamel, minimizing enamel fractures [28].Therefore, excessive adhesion is not desirable as it can cause damage to tooth enamel. The mean force of shear bond strength of the MIM base brackets was compatible with clinical use and similar to several previous studies [28, 37, 38]. However, the force of shear bond strength of the welded base brackets was higher than previous studies [28, 37, 38], and could be slightly above what is necessary for clinical use, which can cause damage to the enamel at debonding, so it should be done more carefully.

Besides the results of the present study, it has to be considered that the force of adhesion is also related to other factors, such as the type of adhesive material used [39, 40], the curvature and size of the bracket base [41, 42], and the quality of the dental enamel, among other factors [38].

CONCLUSION

The null hypothesis tested was rejected since brackets with welded bases presented a significantly higher shear bond strength than brackets with MIM bases. The results of the present study show clinical relevance by indicating that the type of bracket base influences their adhesion to tooth enamel.

ETHICS APPROVAL AND CONSENT TO PARTICIPATE

Not applicable.

HUMAN AND ANIMAL RIGHTS

Not applicable.

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

The data sets analyzed during the current study are available from the corresponding author [K.F] on request.

FUNDING

None.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

Declared none.