All published articles of this journal are available on ScienceDirect.

Evaluation of the Effect of Two Surface Treatment Methods on Shear Bond Strength between Porcelain Veneer and Two Different Zirconia Blocks

Abstract

Introduction:

The aim of the study was to test the effect of two surface treatment methods on shear bond strength between a porcelain veneer and two different zirconia blocks.

Materials and Methods:

Sixty disk-shaped zirconia samples (30 samples of Novi brand and 30 samples of Rainbow brand) were used (diameter of 10 mm and thickness of 4 mm). Based on surface treatment, the samples were randomly divided into 3 groups: control, air-particle abrasion, and Zircos-E Etching Solution. Using the metal mold, the porcelain was veneered on the zirconia surface and then fired. Then, all samples were subjected to shear bond strength testing using a universal testing machine at a speed of 1 mm/min until breaking.

Results:

There was a statistically significant difference between the mean variable shear bond strength of the control group and two other groups, so the shear bond strength in the control group was less than in both groups. And there was no statistically significant difference between the mean variable of shear bond strength in the two groups of “airborne particle abrasion” and “Etching”. There was a statistically significant difference between the mean shear bond strength of the two types of zirconia samples and this amount was lower in Novi than in Rainbow. There was also no interaction between the type of surface preparation and the type of zirconia.

Conclusion:

It can be concluded that surface preparation with air particle abrasion and etching increases the shear bond strength of zirconia to porcelain veneer and the shear bond strength of zirconia and porcelain veneer is affected by the type of zirconia.

1. INTRODUCTION

Porcelain-fused-to-metal (PFM) systems have been widely used as a reliable treatment choice in fixed partial dentures (FPDs) for the past 40 years. One of the advantages of this system is combining two properties: the fracture resistance of the metallic infrastructure and the esthetic appearance of porcelain [1]. Although PFM systems have exhibited good results with long-term clinical success (5-year survival rate of >94%), they have some disadvantages that are mainly related to the presence of metals in their structure, resulting in esthetic challenges, with allergic reactions in rare cases. With advances in technologies and digital systems, all-ceramic restorations have attracted attention to achieve optimal esthetic appearance, biocompatibility, resistance to plaque and acids, light conduction, no dark margin show, no thermal sensitivity, and proper adaptation with natural teeth concerning shade, surface texture, and translucency [2-4]

Ceramics are inherently brittle despite their high compressive strength. In addition, they cannot properly resist tensile forces. Therefore, an infrastructure core is necessary to support veneered porcelain. In recent years, tetragonal polycrystal zirconia stabilized with yttrium oxide (Y-TZP) has been introduced due to its high flexural strength, high fracture resistance esthetic appearance, and unique chemical and mechanical properties as an infrastructure of choice for all ceramic restorations [5]. This infrastructure is fabricated using CAD/CAM technology, and the porcelain is veneered on its surface using layering techniques or a pressing technique; therefore, the zirconia core provides proper support for the porcelain veneer [6]. However, some of the disadvantages of zirconia-based restorations are their opacity and a weak bond between the zirconia core and the veneered porcelain; this weak bond sometimes leads to the separation of the porcelain veneer [7].

It is obvious that an effective bond is necessary between the zirconia core and veneered porcelain for long-term service and to achieve the various advantages of the core in ceramic restorations. Some of the factors affecting the bond strength include; the difference in the thermal expansion coefficients between the core and veneer, the preparation of the framework surface, the shrinkage resulting from the porcelain heat-curing, porcelain type, and the technique to place it, and, the phase change of the zirconia crystals at the zirconia-veneer interface [8].

There are two main preparation techniques have been suggested to improve the bond strength of zirconia and porcelain veneer, including;

(1) The micromechanical bond technique, which includes three subgroups: mechanical (air-borne particle abrasion, diamond and disk grinding, selective infiltration etching), chemical (HF solution, HCL solution, NaOH solution), and laser (Nd:YAG, Er:YAG).

(2) The chemical bond technique has two subgroups: silicon coating and coupling agents (metal primer and zirconia primer) [9].

One of the most commonly used techniques to increase surface roughness and micromechanical retention is air-borne particle abrasion, which increases the total surface area and wettability [10-14]. Some of the variable parameters of this technique include alumina particle size (25‒250 µm), the distance between the nozzle and the sample surface (5‒20 µm), pressure (0.05‒0.45 MPa), and time (5‒30 seconds) [15, 16].

Recently, a new technique, selective infiltration etching (SIE), has been evaluated for roughening of the surface of zirconia, which has improved the bond strength with zirconia compared to the air-borne particle abrasion technique [17]. However, some studies have shown that this technique does not conform to clinical standards [18]. In addition, studies on zirconia etching have shown that the zirconia surface changes significantly after the etching procedure, increasing the shear bond strength [19].

Hydrofluoric acid (HF) can produce resin tags that increase the bond strength between the ceramic and resin cement. Unfortunately, HF cannot adequately etch the zirconia surface because zirconia does not contain glass, has a polycrystalline structure, and is properly resistant to acids. Recent studies have shown micromorphological changes on the zirconia surface after applying 9.5% HF at 25ºC for 24 hours, 95% HF at 80ºC, and 48% HF at 25ºC, indicating that the concentration and temperature can affect the extent of the reaction. Recently, the Zircose-E-etching system has been introduced, which is a mixture of nitric acid, HF, and several other ingredients. This system increases the contact surface area and improves the bond strength between the core and abutment [20].

Sadidzadeh et al. evaluated the effect of a zirconia etching solution on the shear bond strength between zirconia and resin cement and concluded that the solution did not significantly increase the shear bond strength compared to air-borne particle abrasion with 50-µm Al2O3 particles [21].

Different techniques are usually introduced to etch the zirconia surface to increase the micromechanical bond of the resin cement to zirconia, and different types of cement have yielded different results [17, 22]. Different etching techniques affect the whole zirconia surface; however, sufficient studies are not available on the effect of zirconia surface etching on the shear bond strength of the porcelain and the structural strength of zirconia. In addition, currently, there is no consensus about the best surface preparation method to achieve proper bond strength without changing the properties of the zirconia surface. The present study was undertaken to evaluate and compare the effect of the etching technique on the shear bond strength of zirconia to a porcelain veneer using a currently used surface preparation technique for zirconia.

2. MATERIALS AND METHODS

In the present study, two valid and commonly used zirconia brands available on the market were evaluated (Table 1).

2.2. Sample Preparation

First, a sample was prepared using polytetrafluoroethylene (Teflon), measuring 10 mm in diameter and 4 mm in thickness, with a base measuring 4 mm in length. Then, this Teflon sample was scanned using a Dentium scanner. Finally, 60 disk-shaped zirconia samples were prepared (30 samples from zirconia A and 30 from zirconia B) in the same dimensions (10 mm in diameter and 4 mm in thickness with a base measuring 4 mm in length) (Fig. 1) [23], as measured by a digital micrometer (Absolute 500, Kitutoyo, Aura, IL, USA) using a CAD/CAM machine.

| Zirconia Brands | Chemical Composition |

|---|---|

| Novi Dental Product GmbH, Germany | ZrO2 95.5-99%, Y2O3 4.5-6%, HfO2 ≤ 5%, Al2O3 ≤ 0.25%, Other oxides (≤ 0.15%,) |

| Rainbow Trans, Korea | ZrO2 83-96%, Y2O3 4-7%, HfO2 ≤ 5%, Al2O3 ≤ 1%, Other oxides (≤ 0.15%,) |

| Zirconia Groups | Rainbow | Novi | Total | |||

|---|---|---|---|---|---|---|

| Mean | Std. Deviation | Mean | Std. Deviation | Mean | Std. Deviation | |

| Control | 810.7111 | 213.15988 | 784.1444 | 64.88767 | 797.4278 | 153.46132 |

| Airborne particle abrasion | 1137.5750 | 75.96149 | 926.5889 | 134.01768 | 1025.8765 | 152.60481 |

| Etching | 1182.3750 | 98.28429 | 965.7333 | 139.52391 | 1067.6824 | 162.42915 |

| Total | 1034.2400 | 221.93937 | 892.1556 | 138.32741 | 960.4654 | 195.12298 |

The sample surfaces were polished with 600-grit silicon carbide paper (MATADOR, Germany) in one direction and cleaned in an ultrasonic device (Biosonic, Waledent, Germany) containing acetone (Aylar, Iran) and distilled water (Dionizer Device 200M Model, Pars Kimiya Mavad Company, Iran) for 15 minutes. Then the samples from both zirconia products, A and B, were randomly assigned to three groups (Table 2).

2.2.2. Group 2

Surface preparation with air-borne particle abrasion. Surface preparation was carried out with 50-µm aluminum oxide particles for 10 seconds under 2.8 bar at a distance of 10 mm from the surface of the zirconia samples using a micro-etcher (Danaville Engineering, USA). Then, the samples were placed in an ultrasonic device with 96% ethanol for 10 minutes to eliminate any particles from the sandblasting procedure from the zirconia surface [24].

2.2.3. Group 3

Surface preparation with etching.

The samples were immersed in the etching solution (Geumcheon-gu, Seoul, Republic of Korea) according to the manufacturer’s instructions;

The etching solution was prepared by mixing 70% nitric acid (HNO3) and 48% hydrofluoric acid and adding hydrogen peroxide (H2O2) to achieve a 10 wt.% mixed solution. Etching was done for 30 and then the samples were retrieved from the solution and placed in an ultrasonic device (at a frequency of 30 kHz at room temperature) for 30 minutes, followed by rinsing under running water and drying with an air syringe [25].

After surface preparation procedures, porcelain (Initial GC, Zr – FS, GC, Japan) with 2 mm in thickness was placed on the samples using a metallic mold (8 mm in diameter and 2.5 mm in height). Then, the mold was removed, and the porcelain was heat-cured on the samples. Finally, the final thickness of the sample was measured. The samples were then mounted in cold-cured acrylic resin (Acropans, Iran) using a cylindrical mold (a disposable syringe) (Helal Medical Instruments, Iran). Then, each sample underwent a shearing force at the porcelain‒zirconia interface in a universal testing machine (TLCLO, Dartec Ltd., Sturbridge, England) at a crosshead speed of 1 mm/min. The maximum force causing fracture was recorded in Newton (N) [26-28].

Immediately following the shear strength test, visual inspection was performed by two operators, to evaluate the fracture types qualitatively (cohesive and adhesive fractures). The criteria for evaluating the fractures were differences in the color between the zirconia core and the porcelain veneer.

2.3. Statistical Analysis

The Kolmogorov-Smirnov test was used to evaluate the normal distribution of data. Statistical significance was set at P<0.05. In each group with a different surface preparation method, the independent-sample t-test was used to evaluate the effect of zirconia type on the mean shear bond strength at a significance level of 0.05.

3. RESULTS

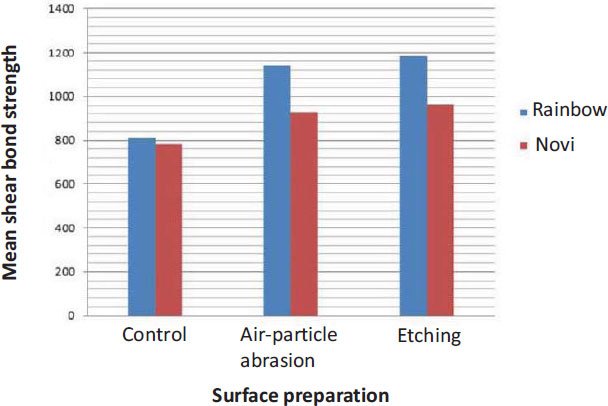

Table 2 and Fig. (2) present the means and standard deviations of shear bond strength values in terms of the surface preparation in two types of zirconia.

The results of the Kolmogorov-Smirnov test and independent-samples t-test showed that:

(1) There were significant differences in the mean shear bond strength values between the two zirconia types with both etching and air-borne particle abrasion surface preparation methods, with a lower mean shear bond strength value in the Novi than in the Rainbow zirconia (P<0.05).

(2) There were no significant differences in the mean shear bond strength values between the two zirconia types in the control groups (P>0.05).

Levene’s test was used to analyze the homogeneity of variances for the shear bond strengths at a significance level of 0.05.

The Kolmogorov-Smirnov test refuted the hypothesis for the homogeneity of shear bond strength variances at a 0.05 significance level. Therefore, Games-Howell post hoc tests were used in the present study, considering the inequality of variances (P<0.05).

Two-way ANOVA was used to evaluate the effect of the surface preparation method on the mean shear bond strength in the two zirconia types at a significance level of 0.05.

The results of the Kolmogorov-Smirnov test and two-way ANOVA showed that:

(1) There were significant differences in the mean shear bond strength values in terms of the surface preparation method (P<0.001). However, the Games-Howell test was used for two-by-two comparisons of the groups at a significance level of 0.05. The results of the Games-Howell test showed that:

(a) There were significant differences in the mean shear bond strength values between the control group and the air-borne particle abrasion and etching groups, with lower mean shear bond strength values in the control group than the two other groups (P<0.001).

(b) There were no significant differences in the mean shear bond strength value between the air-borne particle abrasion and etching groups (P>0.05).

(2) There were significant differences in the mean shear bond strength values between the two zirconia types, with lower shear bond strength values in the Novi than in the Rainbow group (P<0.001).

(3) There were no reciprocal effects between the surface preparation method and the zirconia type. In other words, surface preparation methods had a similar impact on the shear bond strengths of the two zirconia types (P>0.05).

4. DISCUSSION

The highest shear bond strength values in the zirconia samples were related to the etching group and the lowest in the control group.

Air-borne particle abrasion is a commonly used method for the surface preparation of zirconia. This technique increases surface roughness and micromechanical retention [10-13]. The positive effect of air-borne particle abrasion on increasing the shear bond strength of porcelain to zirconia was confirmed in the present study. This study showed that zirconia samples prepared by sandblasting with Al2O3 particles and etching with Zircose-E-solution exhibited the highest shear bond strengths. In a similar study, Dan Liu et al. compared the effects of surface preparation with sandblasting and laser beams on the shear bond strength of porcelain veneered on zirconia, concluding that both methods increased the shear bond strength [29]. Kim et al. also compared the effects of two preparation methods (a liner and sandblasting) on the shear bond strength of porcelain veneered on zirconia. They reported that the sandblasting method yielded a significantly higher bond strength [30]. In addition, Hong-Joo Kim et al. evaluated the effects of different surface preparation methods on the shear bond strength of zirconia to porcelain veneer. Their results showed a significantly higher mean shear bond strength value in the air-borne particle abrasion group than in the liner group [30].

Fisher et al. studied the effects of surface preparation on the shear bond strength of zirconia and porcelain and concluded that surface preparation with sandblasting did not significantly improve the bond between zirconia and porcelain veneer [31]. In addition, Ablul-Hadi et al. studied the effect of sandblasting and sodium hydroxide on the shear bond strength between zirconia and ceramic veneers, reporting that sandblasting did not significantly affect the shear bond strength between zirconia and porcelain veneer, and sodium hydroxide decreased the shear bond strength [32].

In the present study, air-borne particle abrasion was carried out with 50-µm Al2O3 particles 2.8 bar at a distance of 10 mm from the zirconia surface for 10 seconds. The differences between our results and the mentioned studies may be due to the differences in the variable parameters, such as alumina particle sizes, abrasion durations, high pressure, and the type of zirconia used. In particular, when larger particles, higher pressure, and longer times are applied, an increase in the monoclinic phase might lead to microcracks in the glass phase of the veneered ceramic, decreasing the bond strength [33].

The Zircose-E-etching system can increase the contact surfaces and the bond strength between the core and abutment [34]. In our study, this system increased the shear bond strength between zirconia and porcelain veneer compared to the control group. In a similar study, Soo-Bok Her et al. evaluated the effect of the etching technique, a combination of nitric acid and fluoric acid, on the bond strength of zirconia and porcelain veneer, concluding that the tensile bond strength was higher in samples prepared with the etching solution than the control group [35].

The present study showed significant differences in the shear bond strength between the two zirconia types, with a lower mean shear bond strength value in the Novi zirconia than in the Rainbow brand. In a similar study, Ozkurt et al. evaluated the effect of zirconia type and the veneering material on the shear bond strength between zirconia and porcelain veneer. They concluded that the shear bond strength between zirconia and the porcelain veneer was affected by the zirconia type and the veneering material type [36]. In addition, Aboushelib et al. evaluated the effect of zirconia type on the tensile strength with different veneers and concluded that despite the similarity between the chemical structure of zirconia materials, different commercial brands have different structures [37], consistent with the present study, indicating differences in the mean shear bond strength values between the two different zirconia types.

Mosharraf et al. evaluated the effect of different surface preparation methods and zirconia types (colored and white) on the shear bond strength of zirconia core and porcelain veneers and reported that the zirconia type factor did not significantly affect the shear bond strength; however, the surface preparation factor significantly affected the shear bond strength [23]. Therefore, the differences in the results of the present study and some other studies might be attributed to the relative incompatibility between the zirconia and porcelain veneer, differences in study conditions, and the inherent shortcomings of studies, such as the shear bond strength test.

In the present study, each sample was evaluated to determine failure modes after debonding. Most fractures (two-thirds of the samples) were adhesive, and one-third exhibited cohesive failure. Kirmali et al. evaluated the bond strength of zirconia to porcelain veneers and reported that most failures were adhesive [38]. Calvalcanti et al. determined the failure modes of the samples between zirconia and resin cement and reported that adhesive failure was the most frequent failure [39], consistent with the present study.

5. SUGGESTION

The surface topography of the zirconia samples after different surface treatments can be observed by SEM.

CONCLUSION

It can be concluded from the results of the present study that surface preparation with air-borne particle abrasion and etching increased the shear bond strength of zirconia to porcelain veneer. In addition, the zirconia shear bond strength was affected by the zirconia type. In the future, standard techniques are required for testing the bond strength between the zirconia and porcelain veneers. In addition, some manufacturers produce only zirconia, and other brands should be used for the porcelain veneering process, which can lead to some discrepancies.

ETHICS APPROVAL AND CONSENT TO PARTICIPATE

Not applicable.

HUMAN AND ANIMAL RIGHTS

Not applicable.

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

The data and supportive information are available within the article.

FUNDING

This study was supported by Tabriz University of Medical Sciences.

CONFLICT OF INTEREST

Solmaz Maleki Dizaj is a member of the Editorial Advisory Board of The Open Dentistry Journal.

ACKNOWLEDGEMENTS

Declared none.