All published articles of this journal are available on ScienceDirect.

Cyclic Fatigue of Different Nickel-Titanium Rotary Instruments: A Comparative Study

Abstract

Since the introduction of nickel-titanium alloy to endodontics, there have been many changes in instrument design, but no significant improvements in the raw material properties, or enhancements in the manufacturing process. Recently, a new method to produce nickel-titanium rotary (NTR) instruments has been developed, in an attempt to obtain instruments that are more flexible and resistant to fatigue. NTR instruments produced using the process of twisting (TF, SybronEndo, Orange, CA) were compared to NTR instruments from different manufacturers produced by a traditional grinding process. The aim of the study was to investigate whether cyclic fatigue resistance is increased for TF NTR files. Tests were performed with a cyclic fatigue device that evaluated cycles to failure of rotary instruments inside curved artificial canals. Results indicated that size 06-25 TF instruments showed a significant increase (P< .05). In the mean number of cycles to failurewhen compared to the other tested 06-25 NTR. Hence, it can be concluded that size 06-25 TF NTR instruments were found to be significantly more resistant to fatigue than those produced with the traditional grinding process.

INTRODUCTION

All nickel-titanium rotary (NTR) instrument systems currently on the market are constructed from “Nitonol” an alloy that was developed in 1988 [1]. Endodontic treatment has benefited from the resulting instruments. This is due to a combination of unique mechanical properties of the alloy, innovative file design, greater tapers and a crown down instrumentation procedure. As a result, there are now many systems available commercially, that utilize NTR instruments of different designs and dimensions, to facilitate cleaning and shaping procedures [2, 3].

The only concern expressed by dentists using NTR instruments is the fear of fracture during intracanal use, due to excessive torsional and flexural stress [4, 5]. A study which assessed 7159 discarded NTR instruments, showed that 5% had fractured during intracanal use, and that 70% of these fractures were attributed to flexural (cyclic) fatigue [6]. Cyclic fatigue failure is reported to occur unexpectedly without any sign of previous permanent deformation. This occurs due to the alternating tension/compression cycles which instruments are subjected to, when flexed in the region of maximum curvature of the canal [7].

Since the introduction of nickel-titanium alloy to endodontics, there have been many changes in instrument design, but no significant improvements in the raw material properties, or enhancements in the manufacturing process. Recently, a new manufacturing process was developed by SybronEndo (Orange, CA), to create a NRT instrument the Twisted File (TF). It utilizes twisting of a ground blank in combination with heat treatment, to reportedly enhance super-elasticity and increase cyclic fatigue resistance.

To date, there have been few studies published to date on the mechanical properties of TF instruments [8-10]. The purpose of the present study was to investigate whether cyclic fatigue resistance is increased for nickel-titanium rotary (NTR) instruments manufactured using the new twisting process. This was evaluated by comparing TF the to NTR instruments produced by a traditional grinding process.

MATERIALS AND METHODOLOGY

In the present study four different NTR instruments from different manufacturers, of identical sizes (.06 taper and 0.25 tip diameter) were selected and evaluated:

- TF (SybronEndo, Orange, CA, USA).

- M2 (Sweden-Martina, Padova, Italy).

- Profile (Maillefer, Baillagues, Switzerland).

- Flexmaster (VDW, Munich, Germany).

Ten instruments from each manufacturer were tested for cyclic fatigue resistance, resulting in a total of 40 instruments. All instruments had been previously inspected using a measuring microscope for dimensional analysis, and for any signs of visible deformation. None was discarded. All tested instruments, with the exception of TF, were produced using a traditional grinding process. Size 06-25 was selected, being the master apical NTR file in many operative sequences.

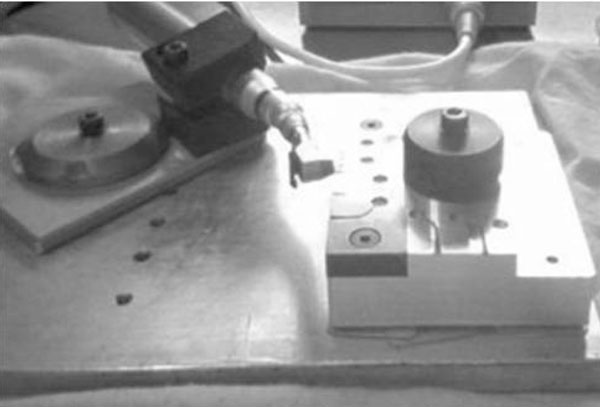

The cyclic fatigue testing device used in the present study has been utilized in previous studies on cyclic fatigue resistance performed by the authors [8, 11, 12]. The device consists of a main frame to which a mobile plastic support is connected for the electric handpiece, and a stainless steel block containing the artificial canals (Fig. 1). The electric handpiece was mounted upon a mobile device to allow precise and reproducible placement of each instrument inside the artificial canal. This ensured three-dimensional alignment, and positioning of the instruments to the same depth. The artificial canal was manufactured by reproducing an instrument’s size and taper. It provided the instrument with a suitable simulated root canal with a 60 degree angle of curvature and 5 mm radius of curvature. The centre of the curvature was 6 mm from the tip of the instrument and the curved segment of the canal was approximately 6 mm in length. The instruments were rotated at a constant speed of 300 rpm using a 16:1 reduction handpiece (W & H Dentalwerk, Burmoos, Austria), powered by a torque controlled electric stepper motor (X-Smart; Dentsply Maillefer, Ballaigues, Switzerland). Torque was set at 2 N/cm.

The testing device.

All instruments were rotated until fracture occurred. The time to fracture was recorded visually with a 1/100-second chronometer. The time to fracture was multiplied by the number of rotations per minute (RPM), to obtain the number of cycles to failure (NCF) for each instrument. The length of the fractured tip was also recorded for each instrument.

Means and standard deviations (SD) of NCF and fragment length were calculated for each system. Data were subjected to one-way analysis of variance (ANOVA) to determine significant differences between groups. When the overall F-test indicated a significant difference, the multiple-comparison Holm t-test procedure was performed to identify the mean that differed from the others. Significance was set at the 95% confidence level.

RESULTS

Mean values ± standard deviation expressed as NCF are displayed in Table 1. A higher number of cycles to failure is due to a higher resistance to cyclic fatigue of the tested instruments A statistically significant difference (P < 0.05) was noted between TF instruments and the other tested NTR instruments produced with a traditional grinding process. TF instruments, size 25, and.06 taper, showed the greatest mean number of cycles to failure. No statistically significant difference (P > 0.05) was noted between ProFile, FlexMaster and M2 NTR instruments

Fatigue Resistance (Mean Number of Cycles to Failure and SD) of Size 25, Taper.06 Instruments

* Significant differences in NCF between TF and the other NTR instruments (P < 0.05).

No significant differences in NCF between M2, FlexMast and Profile (P > 0.05).

ξ No significant differences in fragment length between all NTR instruments (P > 0.05).

Mean length of the fractured segment was also recorded to evaluate the correct positioning of the tested instrument inside the canal curvature, and whether similar stresses were being induced. No statistically significant difference (P > 0.05) in the mean length of the fractured fragments was evident for all of the instruments

DISCUSSION

There have been no scientific methods developed to date, which evaluate the resistance to fatigue of NTR instruments. Differences in testing devices used for evaluation can lead to different results, but so far there has been no device or method for fatigue testing incorporated into international standards for endodontic instruments. Furthermore, there is no testing protocols approved by the International Standard Organization (ISO) to establish minimum standards for an instrument’s cyclic fatigue resistance. Nevertheless, with cyclic fatigue failure appearing to be the main mechanism leading to intracanal failure, fatigue testing of NiTi rotary instruments is probably the most useful tool to understand an instruments’ fatigue properties. The cyclic fatigue testing device used in the present study has been utilized in previous studies of cyclic fatigue resistance [8, 11, 12]. The purpose of the present study was to investigate whether cyclic fatigue resistance is increased for nickel-titanium rotary (NTR) instruments manufactured using the new twisting process. This was evaluated by comparing TF NTR instrument produced by the process of heating and twisting to NTR instruments produced by traditional grinding methods. Results showed that size 06-25 TF instruments were significantly more resistant to cyclic fatigue than the other tested size 06-25 NTR instruments.

In a recent study [13] it has been determined that the fatigue life of NTR instruments is not significantly affected by differences in cross-sectional shape. Therefore, the improvement in cyclic fatigue resistance for size 06-25 TF instruments appears to be related to the manufacturing process. Moreover, it has been shown [14] that the design of the cutting flutes does not influence the fatigue resistance of instruments that are the same size.

The TF technology was developed to increase NTR instrument resistance to cyclic fatigue, and provide superior mechanical properties. The present in vitro evaluation of resistance to cyclic fatigue provided promising results. The innovative manufacturing process developed by SybronEndo, involving twisting a ground blank and heat treating it, produced a new instrument (TF) significantly more resistant to fatigue than NTR instruments produced with the traditional grinding process.

Results can be explained by the fact that the traditional grinding process has many drawbacks [15]. More precisely, cutting across the grain of the crystalline structure of the nickel-titanium wire limits the overall strength of the instruments, due to the formation of micro-cracks and defects along the surface of the instruments and within the internal structure [16-18]. These defects can cause stress concentration points that weaken the instruments and can lead to intracanal failure. Moreover cracks can propagate to failure at a stress level lower than the stress usually encountered during canal instrumentation, leading to sudden, unexpected file breakage [19, 20].

The preliminary findings of the present study must be confirmed by further investigations, which should evaluate other clinically relevant mechanical properties of the TF instruments. Additional studies are also necessary to improve correlations between in vitro and in vivo fatigue resistance of NTR instruments.

CONCLUSION

It can be concluded that the new twisting process produced size 06-25 NTR instruments (TF) significantly more resistant to fatigue than those produced with the traditional grinding process.