All published articles of this journal are available on ScienceDirect.

Effect of Finishing and Polishing on The Surface Roughness of Bulk Fill Composites

Abstract

Objective:

The aim of this in vitro study was to compare the effect of three finishing/polishing systems on the surface roughness (Ra) of conventional and Bulk-fill composite resins.

Materials and methods:

The Ra values of three different brands of Bulk-fill composites (Filtek Bulk-fill®, 3M ESPE; SonicFill Bulk-fill®, Kerr; SDR Bulk-fill®, Dentsply) were tested and compared with the Ra of a conventional composite (Filtek XT Z350®, 3M ESPE). A total of 30 discs (10 mm × 2 mm) were fabricated from four test materials and divided into three groups (n = 10/group) depending on the three finishing/polishing systems used (Astropol®, Ivoclar Vivadent; PoGo®, Dentsply; Sof-LexTM®, 3M ESPE). The Ra of each specimen was recorded with an optical profilometer (Contour-GT-X®, USA). ANOVA and Tukey’s tests were used for statistical analysis.

Results:

Statistically significant differences (P < 0.05) were observed between the Ra values of all composite materials tested with three finishing/polishing systems. Among composite materials, only Group-III showed a significant difference (P = 0.003) in Ra obtained using all three finishing/polishing systems. SDR Bulk-fill® and Filtek XT Z350® showed the highest (0.810 ± 0.373 µm) and lowest (0.365 ± 0.119 µm) Ra values, respectively. Individually, the highest Ra was recorded for SDR Bulk-fill® when it was finished/polished with the Astropol® system. SonicFill Bulk-fill® and SDR Bulk-fill® composites exhibited the lowest Ra values when they were finished with the PoGo® system.

Conclusion:

Finishing and polishing techniques greatly affect the surface roughness of different Bulk-fill composites because variations in the surface roughness were observed for all tested composite materials. Filtek XT Z350® exhibited the lowest surface roughness, while SDR Bulk-fill® exhibited the highest surface roughness among the tested composite materials.

1. INTRODUCTION

For many years, composite resins have allowed clinicians to provide esthetic and strong restorations to their patients as an alternative to amalgam fillings [1]. However, there are several advantages of using regular composites; specifically, dentists have to spend more time and effort on placing composite resin restorations because the composite has to be placed in increments to ensure proper depth for the curing light, which makes it difficult to achieve good adaptation to cavity walls [2]. Manufacturers have begun to address this concern by introducing new composite resins (e.g., Bulk-fill), which are specifically designed for posterior use and allow dentists to place restorations faster and easier [3].

New Bulk-fill composites reduce the need for the incremental placement of material [4]. In addition, new Bulk-fill composites reduce polymerization shrinkage, provide excellent adaptation and handling, prevent postoperative sensitivity, provide lasting marginal integrity, improved aesthetics, durability, and more working time, and eliminate the need for placing and curing multiple layers of composite (high depth of curing) for direct posterior composite restorations [5]

The longevity of any restoration is one of the most important factors determining its success. A highly polished surface restoration greatly contributes to an increase in longevity and esthetic quality of composite restoration [6-8]. Oral biofilms attach to both teeth surfaces and dental material surfaces in oral cavities. Oral biofilms are the source of pathogenesis for periodontal disease, dental caries, secondary caries, and peri-implantitis, which ultimately lead to the failure of restorations [9, 10]. Many studies have demonstrated that unpolished surfaces/rough surfaces can accumulate more dental biofilm than polished surfaces, including resin-based composites, ceramics, implant abutments, and denture bases [11, 12]

Smooth, highly polished composite restorations are esthetically pleasing, allow them to easily maintain oral hygiene, and, owing to less biofilm formation, are more long-lasting than rough restorations [13, 14]. The material surfaces are prone to discoloration, plaque accumulation, gingival irritation, and secondary caries owing to inadequate finishing/polishing procedures. The rough surface may also affect the wear properties and marginal integrity of posterior composite resin restorations [15-17]. Various brands of finishing and polishing systems are available that produce different surface characteristics for composite restorations. However, there is a lack of sufficient information regarding the best method and material used to finish and polish Bulk-fill composites. Therefore, the aim of this in vitro study was to use a profilometer to investigate and compare the surface roughness (Ra) of various Bulk-fill composites polished with three different brands of finishing and polishing systems. The null hypothesis was that the surface of all tested Bulk-fill composites would exhibit the same Ra across all three finishing/polishing systems.

2. MATERIALS AND METHODS

This study was approved by the institutional review board/CDRC of King Saud University (Reg. # E-18-3347). In this study, one conventional [Filtek XT Z350® (FiltekZ350)] and three Bulk-fill [Filtek Bulk-fill® (Filtek-BF); SonicFill Bulk-fill® (SonicFill-BF); SDR Bulk-fill® (SDR-BF)] commercially available resin-based composites with different types of resin and filler particles were tested to determine Ra for three finishing and polishing systems [Astropol® (Astropol); PoGo® (PoGo); Sof-LexTM® (SofLex)] (Table 1).

2.1. Sample Size Calculation and Specimen Preparation

At the alpha of 0.05, with the power of 0.95, and the effect size/marginal error of 0.5, the total sample size for the four composite materials to be finished and polished across the three systems was 120. Using a stainless steel mold, 30 discs with a 10-mm diameter and 2-mm thickness were fabricated from each composite material. Each material was placed in a stainless steel mold and pressed over the material using a clear matrix strip (Mylar strip, Yates and Bird/Motloid, Chicago, IL, USA); thus, a smooth bubble-free surface of each specimen was produced. Then, all disc-shaped specimens were light-cured for 20 s using a handheld light-curing unit (Spectrum 800; Dentsply Inc., York, PA, USA) with the output of 1340 MW/cm2. Next, the roughening of all specimen surfaces was performed using AUTOMATA and 120-grit carbimet paper discs at 20 rpm for 20 s.

2.2. Finishing and Polishing

After roughening, all 30 specimens from each composite material group were further randomly subdivided (random draw method) into three groups of 10 specimens each to be finished/polished, depending on the three types of finishing/polishing procedures used in the study. Each specimen was subjected to the finishing/polishing procedure according to the manufacturer’s instructions regarding the speed of handpiece, material application method, quantity of material, water utilized, and time used to apply the handpiece (Table 1). As the specimens had a flat surface, the motion of the handpiece was simply from right to left. The finishing/polishing procedure was performed by the same operator to prevent interoperator variations in the surface characteristics of the specimens. Then, the samples were kept in normal saline at room temperature (15–20°C) until the time of Ra measurement.

2.3. Surface Roughness Test

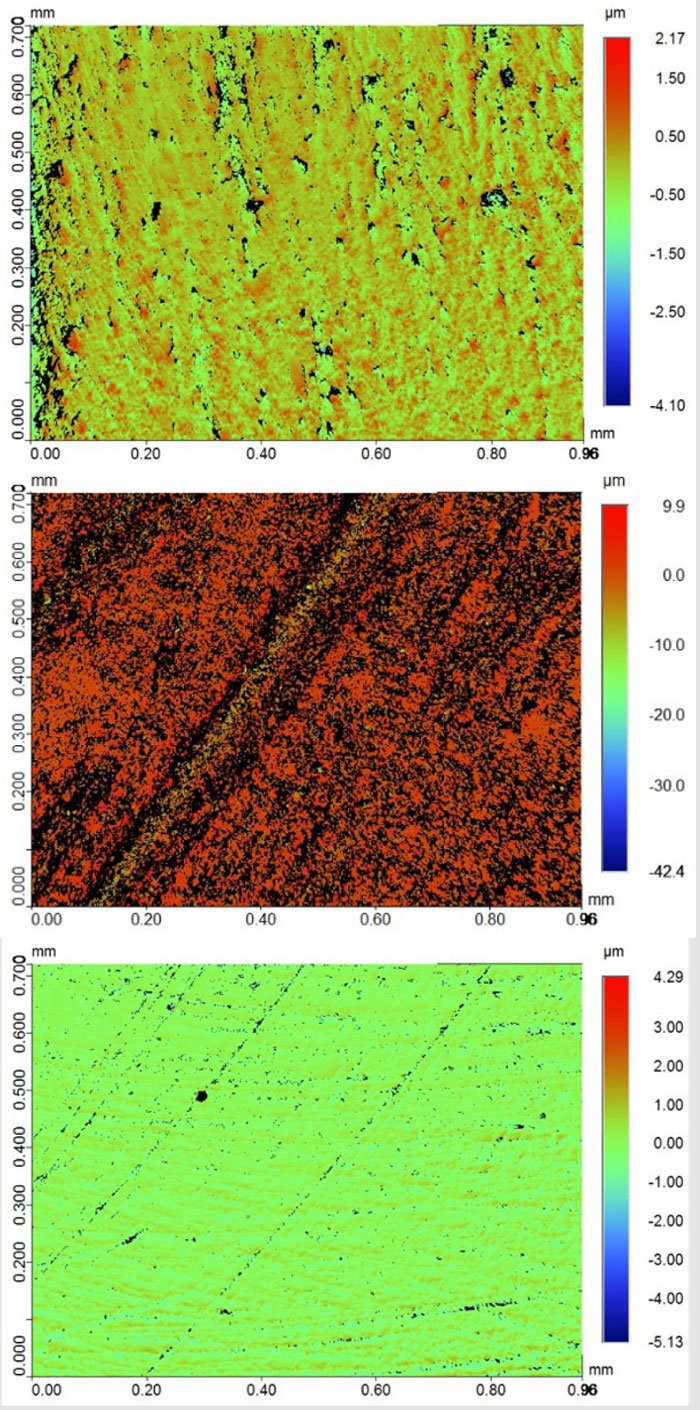

The Ra values of all group specimens were determined in micrometers (μm) using a three-dimensional (3D) profilometer (Contour-GT-X®, 3D Optical Microscope, Bruker Nano Surfaces Division, San Jose, CA, USA). The 3D specimen surfaces were scanned using a 3D profiling system, and the Ra of the specimens were calculated using a 3D software (Vision64®, Operation and Analysis Software, Bruker Nano Surfaces Division, San Jose, CA, US). Three traces were recorded for each specimen perpendicular to the finishing and polishing scratch directions, and the mean value of the three traces was considered as the final Ra value for each specimen (Fig. 1).

2.4. Data Analysis

The data were analyzed using the SPSS version 21.0 (IBM Inc., Chicago, IL, USA) statistical software. The mean Ra values (μm) were tabulated in columns, and descriptive statistics (mean ± standard deviations) were used to describe the quantitative outcome of each group. The two-way analysis of variance was used to compare the mean Ra values of four composite materials tested (FiltekZ350, Filtek-BF, SonicFill-BF and SDR-BF) using three polishing systems (Astropol, PoGo, SofLex). Post Hoc Tukey’s multiple comparison tests were used to compare the mean Ra values between different pairs of polishing systems and composite materials. The p-value of <0.05 was used as the cut-off for statistical significance.

| S. No. | Groups | Trade Name | Manufacturer | Description |

|---|---|---|---|---|

| Composite materials | FiltekZ350 | Filtek Z350® conventional composite | 3M ESPE |

Resin: BisGMA, UDMA, TEGDMA, and BisEMA resins Filler: Combination of non-agglomerated/non-aggregated 20 nm silica filler, non-agglomerated/non-aggregated 4–11-nm zirconia filler and aggregated zirconia/silica cluster filler (20-nm silica and 4–11-nm zirconia particles) |

| Filtek-BF | Filtek Bulk-fill® composite | 3M ESPE |

Resin: BisGMA, BisEMA, UDMA, and Procrylat Filler: Combination of ytterbium trifluoride and zirconia/silica particles |

|

| SonicFill-BF | SonicFill Bulk-fill® composite | Kerr |

Resin: BisGMA, TEGDMA, EBPDMA Filler: SiO2, glass, oxides, chemicals |

|

| SDR-BF | SDR Bulk-fill® composite | Dentsply |

Resin: Modified UDMA, TEGDMA, EBPDMA Filler: Barium and strontium F-AI-silicate |

|

| Finishing and Polishing Materials | Astropol | Astropol® | Ivoclar Vivadent | 3-Step finishing and polishing system: Astropol F: Silicon carbide particles and color pigments. Astropol P: Silicon carbide particles and color pigments. Astropol HP: Diamond particles, aluminum oxide, titanium oxide, and iron oxide |

| PoGo | Enhance® PoGo® | Dentsply | 1-Step diamond micro polishers composed of pre-mounted, diamond-impregnated polishers | |

| SofLex | Sof-LexTM® Spiral finishing and polishing wheels |

3M ESPE | 2-Step finishing and polishing system composed of a thermoplastic elastomer impregnated with aluminum oxide particles |

3. RESULTS

In this study, the Ra values of four composite restorative materials were measured and compared. The measurements were recorded after the specimens of each composite group were subjected to three different finishing/polishing procedures/protocols. The normality of all data was evaluated with the Shapiro–Wilk test and determined to be normally distributed for all groups (P > 0.05).

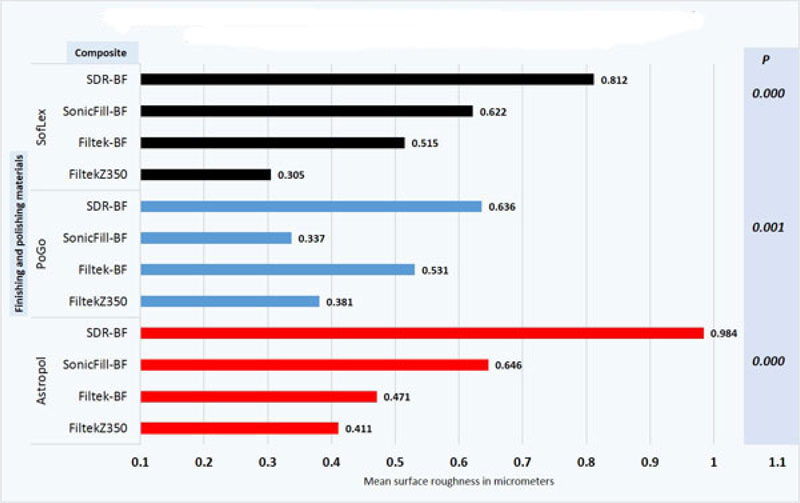

Variations in the Ra values produced with three finishing/polishing systems existed among the composite materials tested in this study. Statistically significant differences (P < 0.05) were observed between the Ra values of all composite material groups tested across the three finishing/polishing systems (Fig. 2). The two-way ANOVA analysis did not indicate a significant difference between the three finishing systems within FiltekZ350, Filtek-BF, and SDR-BF (P > 0.05). However, only SonicFill-BF showed a significant difference (P = 0.003) in the Ra values with all three finishing/polishing systems (Table 2). In addition, there was an interaction between materials and finishing systems (P-value = 0.044).

| Composite Material | Finishing/Polishing System | Mean | Std. Deviation | *ANOVA P-value | Lower Bound | Upper Bound |

|---|---|---|---|---|---|---|

| FiltekZ350 (n = 10) |

Astropol | 0.411 | 0.109 | 0.183 | 0.261 | 0.562 |

| PoGo | 0.381 | 0.185 | 0.230 | 0.532 | ||

| SofLex | 0.305 | 0.064 | 0.154 | 0.455 | ||

| Total | 0.365 | 0.119 | 0.215 | 0.516 | ||

| Filtek-BF (n = 10) |

Astropol | 0.471 | 0.127 | 0.610 | 0.320 | 0.621 |

| PoGo | 0.531 | 0.154 | 0.380 | 0.682 | ||

| SofLex | 0.515 | 0.137 | 0.364 | 0.665 | ||

| Total | 0.505 | 0.139 | 0.354 | 0.656 | ||

| SonicFill-BF (n = 10) |

Astropol | 0.646 | 0.210 | 0.003 | 0.496 | 0.797 |

| PoGo | 0.337 | 0.039 | 0.187 | 0.488 | ||

| SofLex | 0.622 | 0.280 | 0.471 | 0.773 | ||

| Total | 0.535 | 0.176 | 0.384 | 0.686 | ||

| SDR-BF (n = 10) |

Astropol | 0.984 | 0.528 | 0.159 | 0.833 | 1.135 |

| PoGo | 0.636 | 0.233 | 0.485 | 0.786 | ||

| SofLex | 0.812 | 0.360 | 0.661 | 0.963 | ||

| Total | 0.810 | 0.373 | 0.659 | 0.961 |

| Finishing/Polishing System | Composite Material | Groups | *Sig. |

|---|---|---|---|

|

Astropol |

FiltekZ350 | Filtek-BF | 0.970 |

| SonicFill-BF | 0.302 | ||

| SDR-BF | 0.001 | ||

| Filtek-BF | SonicFill-BF | 0.552 | |

| SDR-BF | 0.002 | ||

| SonicFill-BF | SDR-BF | 0.069 | |

|

PoGo |

FiltekZ350 | Filtek-BF | 0.210 |

| SonicFill-BF | 0.939 | ||

| SDR-BF | 0.009 | ||

| Filtek-BF | SonicFill-BF | 0.210 | |

| SDR-BF | 0.067 | ||

| SonicFill-BF | SDR-BF | 0.002 | |

|

SofLex |

FiltekZ350 | Filtek-BF | 0.223 |

| SonicFill-BF | 0.027 | ||

| SDR-BF | 0.000 | ||

| Filtek-BF | SonicFill-BF | 0.750 | |

| SDR-BF | 0.042 | ||

| SonicFill-BF | SDR-BF | 0.305 |

Among the composite materials, SDR-BF and FeltikZ350 showed the highest (0.810 ± 0.373 µm) and lowest (0.365 ± 0.119 µm) Ra values, respectively (Table 2). Individually, the highest Ra (0.984 ± 0.528 µm) was recorded for SDR-BF when it was finished/polished with Astropol. SonicFill-BF (0.337 ± 0.039 µm) and SDR-BF (0.636 ± 0.233 µm) composite materials obtained their lowest Ra values when they were finished/polished with the PoGo system.

Multiple comparisons of the Ra values of all composite test groups for three finishing and polishing systems are shown in Table 3. The SofLex fishing/polishing system revealed the highest number of significant differences among the composite groups. This result also confirmed the presence of variations between the Ra values of the composites produced using different finishing and polishing systems.

4. DISCUSSION

In this in vitro research study, the Ra of four commonly used composite restorative materials that were finished/polished with three different systems were evaluated using the test specimens of identical shape and dimensions under the same testing conditions using a 3D non-contact profilometer. The recorded Ra values were useful for the assessment and comparison between the composite materials tested.

The methodology used in this study for measuring Ra values using a 3D non-contact profilometer provides good resolution of the traced surface and has been reported by several researchers to be the optimal method for measuring Ra [10, 12, 18-20]. The advantages of an optical profilometer are that it uses a beam of light to detect small variations, provides a quantitative aspect through the calculation of Ra, and the same specimens can be reused and reobserved after successive time intervals.21 The recorded Ra value is a helpful general indicator of surface topography; it is useful and easy to understand value; therefore, it is possible to compare Ra of different materials and also compare the results with those from other studies and standards.18−21

Previous studies have confirmed the differences in Ra of various composite restorative materials that were finished and polished by different materials and systems using standardized in vitro specimen preparations [22, 23]. Most Ra tests provide limited information/correlation with clinical performance; nevertheless, in vitro experiments allow the comparative assessment and ranking of chemically different materials under standardized testing conditions. However, testing conditions that are similar to the clinical scenario are always considered to be useful [10, 12, 19, 22]

According to the results of this study, significant differences in the Ra of tested composite materials that were finished and polished by three different systems were revealed. Among the tested materials, FiltekZ350 (conventional composite) possessed the smoothest surface with the lowest Ra values (0.365 ± 0.119), and SDR-BF (Bulk-fill composite) possessed the roughest surface with the highest Ra values (0.810 ± 0.373). Thus, based on these results, the null hypothesis of the absence of difference in Ra between the materials after finishing/polishing with different systems was rejected.

In this study, the order of surface roughness ranked according to composite groups was Filtek XT Z350® < Filtek Bulk-fill® < SonicFill Bulk-fill® < SDR Bulk-fill®. The overall lowest Ra value was recorded for the control FiltekZ350 of the conventional composite. Filtek XT Z350® contains a combination of a non-agglomerated/non-aggregated (20-nm nanosilica filler) and loosely bound agglomerated zirconia/silica nanocluster with the filler size of 5–20 nm and a cluster particle size of 0.6–1.4 μm. As this composite contains nanofillers, it has lower surface roughness than other materials after polishing. Filtek-BF exhibited the next smoothest surface, and multiple comparisons revealed non-significant differences between this group and the FiltekZ350 control group. These non-significant differences can be attributed to the brand similarity of the two groups.

In our study, SDR Bulk-fill® exhibited the roughest surfaces with the highest Ra values. This finding is similar to the results reported by Kumari et al., [22] Nair et al., [18] and other researchers. This reported high Ra is attributed to the lower filler loading and polymerization modulator that is chemically embedded at the center of the polymerizable resin, which is the backbone of SDR Bulk-fill®.23−25

Among all groups tested with each finishing/polishing material, the lowest Ra was observed for Filtek XT Z350® that was polished with Sof-LexTM®. Previous studies have reported that aluminum oxide discs are ideal for producing low Ra. [7, 22, 23]. This is attributed to the ability of the Sof-LexTM® system to abrade filler particles and resin matrix at equal rates without dislodging the filler particles and gouging into the material. [18, 22, 23] On the other hand, the smoothest surfaces of SDR Bulk-fill® and SonicFill Bulk-fill® were obtained when they were finished with the PoGo® system. A previous study26 on the effect of a one-step polishing system on the Ra of composite concluded that among the polishing systems tested, the PoGo system produced the smoothest finishing for all conventional composite resins.26 The highest Ra value was recorded for SDR Bulk-fill® when it was finished with the Astropol® system. This result was obtained possibly due to the coarser abrasive particles in the Astropol® system than in other systems [27].

Some limitations of this study are the flat surface of the sample (which is absent in clinical restorations) and the limitations associated with the in vitro research studies, and the absence of clinical environment because there may be changes in in vivo results. In this study, the Ra of the groups was measured and compared after roughening the specimens, and for future investigations, it is advised to do the initial Ra as well for a better comparison. Further research using other available systems with larger sample size is recommended for future studies. Further studies with samples prepared in the teeth to simulate convex and concave tooth surfaces are required to investigate how these resins and polishing systems will perform under clinical conditions.

CONCLUSION

Within the limitations of this study, the following conclusions can be made:

- Variations existed in the surface roughness of composite materials that were finished/polished with different systems.

- Finishing and polishing techniques greatly affect the surface roughness of different Bulk-fill composites.

- Among the tested composite materials, Filtek Z350® showed the smoothest surface/lowest surface roughness values out of all polishing systems tested.

- Among the Bulk-fill composites, SonicFill Bulk-fill® that was polished with the PoGo® system produced the best results in terms of surface roughness.

- SDR Bulk-fill® exhibited the highest surface roughness, which was greatly reduced when the material was polished with the PoGo® system.

ETHICS APPROVAL AND CONSENT TO PARTICIPATE

Not applicable.

HUMAN AND ANIMAL RIGHTS

Not applicable.

CONSENT FOR PUBLICATION

Not applicable.

AVAILIBILITY OF DATA AND MATERIALS

Not applicable.

FUNDING

None.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial or otherwise.

ACKNOWLEDGEMENTS

Declared none.