All published articles of this journal are available on ScienceDirect.

Investigating the Effect of Different Metal Sheets on Reducing Radiation Behind Intraoral Digital Phosphor Plates During Intraoral Radiography using Gray Value

Abstract

Purpose:

To assess the efficacy of metal sheets with different thicknesses on reducing the radiation behind the photostimulable phosphor plate (PSP) during intraoral periapical examinations.

Materials and Methods:

In this study, a phantom head was used to investigate the effect of using metal sheets of aluminum, stainless steel, and copper with three thicknesses of 0.5, 0.75 and 1mm on reducing the radiation behind PSP. Images were acquired at 66 kVp 8 mA, and 0.16 s using the long-cone paralleling technique. The images were saved and exported to DICOM format without any post-processing. Then, they were transferred to an image processing software (Mimics, Materialize, Leuven, Belgium), and their mean gray values (MGV) were determined. The acquired data were statically analyzed for accessing the significant difference in groups means using ANOVA, and the means of groups were compared using Tukey’s test procedure.

Results:

The MGV of the second PSP differed significantly from those PSPs slotted with various metals (p<0.001). The MGV for lead and stainless steel at 0.5 mm thickness was insignificant (p = 0.852), but differed significantly from other metals. The MGV for PSPs with 0.75 mm stainless steel and 1 mm copper slots were varied significantly from those of all other PSP and metals. The 1 mm copper group was significantly different from all other groups (p<0.001).

Conclusion:

Using the mean gray value of the PSP, the use of various metal sheets of different thicknesses could effectively reduce the radiation behind the PSPs during periapical radiographs.

1. INTRODUCTION

Recent advances in radiology techniques have introduced substantial diagnostic benefits in dentistry [1]. In X-ray radiology, despite low dose received by a patient during radiography, there are still concerns about the carcinogenicity of X-rays and exposure to ionizing X-rays. Exposing to X-ray radiation is always can be accompanied by some risks [2]. However, various protective devices and techniques have been used to reduce the levels of radiation received by patients.

The development of digital radiography has led to many improvements in the field of diagnostic imaging. Features such as the wider amplitude of radiation and greater sensitivity of digital receptors and sensors have reduced the amount of radiation that patients are exposed [3]. Digital radiographic sensors have two broad categories of photostimulable phosphor plates (PSPs) and silicon devices. The PSP systems do benefit from being user-friendly, compared to conventional intraoral radiology films [4].

In conventional film-based intraoral radiography, the amount of radiation passing through a PSP is reduced by a lead foil. This lead foil, which is a protective metal sheet plays two major roles in dental x-ray films. First, it reduces the transmitted radiation and the absorbed dose by the tissue behind the film envelope. Second, it prevents backscatter radiation from the tissues to maintain image quality [5, 6]. However, due to shorter exposure time for image acquisition, lead foils are rarely used in digital radiography. However, the necessity of shielding materials still cannot be neglected, based on the “as low as reasonably achievable, (ALARA)” principle [7].

On the other hand, there have been many concerns over lead toxicity over the past years, and lead poisoning in both children and adults has been well documented [8]. There are also reports of the need to modify the criteria due to the corrosion of the lead sheet when used as a structural shield [9]. Lead foils, when outside an envelope, often come direct contact with fingers and mouth tissues and may lead to deleterious effects [10]. On the other hand, concerns about lead environmental pollution and its proper disposals, have severely restricted its uses. The EU directive “Restriction on the Use of Hazardous Certain Materials” for electrical and electronic equipment has forbidden the use of lead in electrical appliances since July 1, 2006. Therefore, lead-free products in healthcare and industrial applications are in high demand [11].

Much research had been done on the use of non-lead metals to reduce the role of lead protectors. However, the use of other metal sheets as an alternative to lead foils requires more scientific attention. The purpose of this study was to evaluate the effect of different metals, including stainless steel, copper and aluminum with different thicknesses, on reducing radiation exposure behind photostimulable phosphor plates (PSPs) during periapical intraoral examinations.

2. MATERIALS AND METHODS

Phantom head (DXTTR III X-ray Trainer) was used for taking the required images in all experiments. The phantom head consisted of an adult human skull with jaws and normal teeth covered by plastic material. The plastic materials were composed of substances that were equivalent to actual tissue in terms of absorption and attenuation of radiation. In order to investigate the effect of different metals on radiation behind PSPs, three common metal sheets, including aluminum, stain less steel, and copper with thicknesses of 0.5, 0.75 and 1.0 mm were prepared.

As ISO recommends a film packet thickness below 2.0 mm, the thicknesses of our pocket, including the PSP and metal sheet, were within the recommended operational thickness [12]. The metal sheets were similar in size to the PSP Vista Scan phosphor plate system (Dürr Dental, Beitigheim -Bissingen, Germany), size 2, 40.0 mm × 30.0 mm. Since lead foils are commonly used in conventional radiography films, this type of foils was also used as a group for comparison.

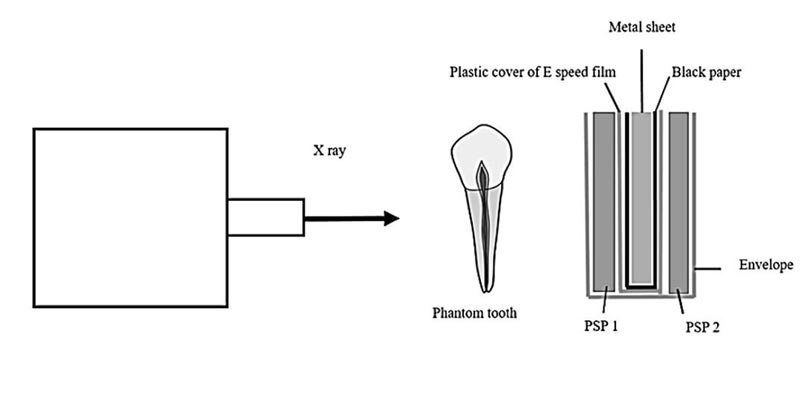

The back of each PSP was marked with different colors, a blue arrow for the first PSP and a green arrow for the second PSP, to differentiate the PSPs. Also, in order to differentiate radiographs, for the first PSP the dot was placed in the occlusal and for the second PSP the dot was placed in the apical. Two fixed PSPs were used for all the experiments. The lead foil in the E Speed Carestream Kodak Films was then inserted inside the black paper and plastic cover of E Speed Carestream Kodak Films and placed between the PSPs and they were all placed inside a plastic envelope (Fig. 1).

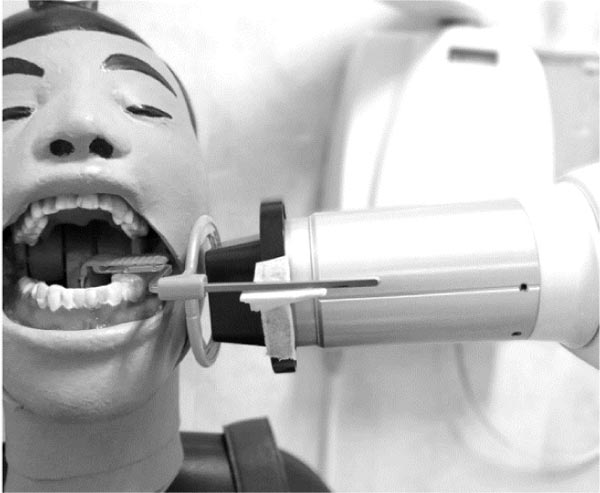

To help positioning the image receptor and to reproduce the parallel technique, the region of lower mandibular molars was selected from lingual cusp of first left premolar to the mesial of third molar. Initially, PSPs alone were inserted inside the plastic envelope. Using a 30 cm long cylindrical collimator equipped with a rectangular PID (Dentsply / Rinn XCP Corporation, Elgin, IL, USA), and a film holder (Rinn-Endo-Ray) was set at a distance 2 cm from the phantom face. For acquiring the images the vertical and horizontal angulations were set to 0° and 90°, respectively. In addition, the object-detector distance of 1 cm were used throughout the experiments (Fig. 2).

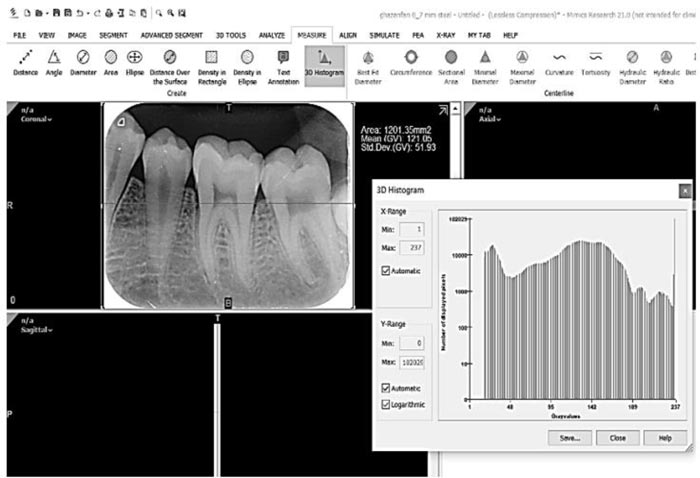

Radiation conditions were set at 66 KVp at 8 mA and 0.16 s. Imaging was performed by a dental X-ray unit (Planmeca OY, Helsinki, Finland) and the images were immediately scanned with Scanora 5.0 software (Sorodex, Helsinki, Finland). After saving, all of the image were exported to DICOM format without any post-processing. Then, they were transferred to mimics software (Mimics, Materialize, Leuven, Belgium) in order to measure the mean gray value of each PSPs. In an 8-bit grayscale image, each pixel may take a value from 0 to 256. A 0 value represents a black pixel (minimum density) and 256 represents a white pixel (maximum density).

The mean gray value of the region of interest that was equal to the total area of PSP, was measured with the rectangular density region icon of the software. The histogram of each image was also evaluated. The histogram graphically displays the distribution of pixels amongst the grayscale values. The x-axis shows the gray value (from 0 to 256), the y-axis shows their frequency in the image (Fig. 3). The same procedure was applied to the other metal sheets used in the study. All experiments were repeated 10 times and immediately scanned.

2.1. Data Analysis

To investigate any significant difference between the mean gray values of the groups, one-way ANOVA, with 11 groups and 10 replicates for each group, was performed. Initially, the assumption for normality of data for each group, required for the ANOVA test, was verified by the Kolmogorov-Smirnov test. Then, using Tukey’s test, all experiments were compared in pairs for each group of the second PSP. All statistical analyses were performed using the SPSS statistic software, v.22 package (IBM crop, formerly SPSS Inc, Chicago, USA), based on 95% confidence and a margin error of 0.5%.

3. RESULTS

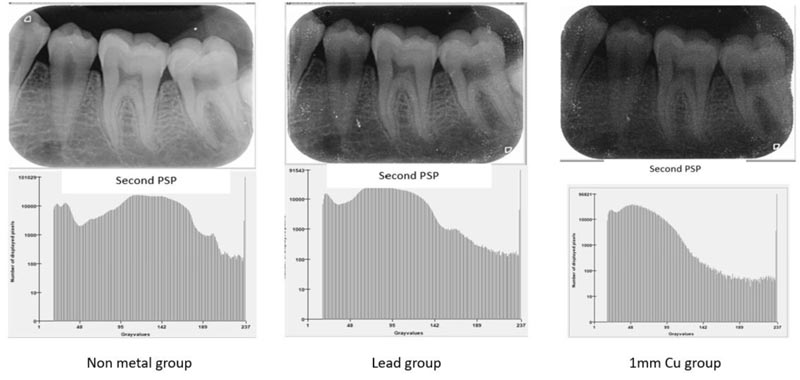

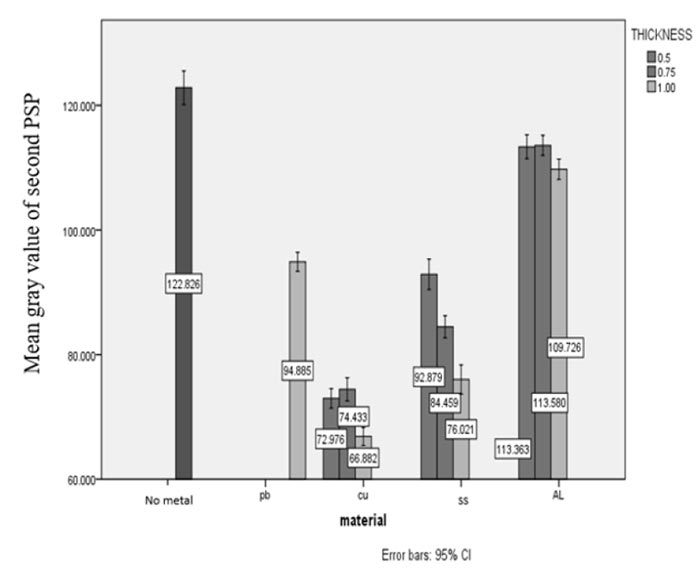

Typical images and histograms of the second images of different metals are shown in Fig. (4). The histogram of the second images in the non-metal group had a uniform distribution with a peak mean gray value of 122.82 locating in the mid region. The distribution of the gray values in the histogram of the metal groups is skewed to the right, indicating more dark pixels in these images. Comparison of the histograms of different groups indicated that as the atomic number increased from aluminum to stainless steel (iron) and to copper, and also by increasing the metal thickness from 0.5 mm to 1mm, the frequency of the light gray shades decreased and the dark gray shades increased. For example, the mean gray value 94 for the lead group was 94.88 and for the 1mm Cu group it was 66.88.

| Groups | n | Mean | Std. Deviation | Std. error | 95% Confidence Interval for Means | Min. | Max. | |

|---|---|---|---|---|---|---|---|---|

| Lower Bound | Upper Bound | |||||||

| No metal | 10 | 122.82 | 3.77 | 1.19 | 120.12 | 125.52 | 117.46 | 129.57 |

| Pb | 10 | 94.88 | 2.12 | 0.67 | 93.36 | 96.40 | 91.59 | 97.96 |

| Cu 0.5mm | 10 | 74.97 | 2.19 | 0.69 | 71.40 | 74.54 | 70.17 | 76.03 |

| Cu 0.75mm | 10 | 72.43 | 2.59 | 0.82 | 72.57 | 76.28 | 71.68 | 78.57 |

| Cu 1mm | 10 | 66.88 | 2.00 | 0.63 | 65.44 | 68.31 | 63.22 | 69.86 |

| SS 0.5mm | 10 | 92.87 | 3.40 | 1.07 | 90.44 | 95.31 | 86.02 | 96.55 |

| SS 0.75mm | 10 | 84.45 | 2.48 | 0.78 | 82.67 | 86.23 | 80.09 | 88.81 |

| SS 1mm | 10 | 76.02 | 3.28 | 1.03 | 73.66 | 78.37 | 72.75 | 82.00 |

| Al 0.5mm | 10 | 114.36 | 2.69 | 0.85 | 111.43 | 115.29 | 110.15 | 116.91 |

| Al 0.75mm | 10 | 113.58 | 2.25 | 0.71 | 111.96 | 115.19 | 111.34 | 118.69 |

| Al 1mm | 10 | 109.72 | 2.26 | 0.71 | 108.10 | 111.34 | 106.26 | 113.57 |

The descriptive statistics for MGV data for the images in the second PSP are presented in Table 1 and graphical comparison for the calculated means with their corresponding 95% confidence intervals is presented in Fig. (5). The highest mean is 122.82 for no metal PSP which indicates the addition of any metal will cause a reduction in MGV. Also, with an increase in the thickness of the metals, the MGV of the second PSP decreased. The minimum MGV belonged to the copper group with a thickness of 1 mm with MGV = 66.88. A lower MGV indicates a darker image and when an image is darker, less radiation passes through a metal between the PSPs. Thus, as Table 1 indicates, the lowest amount of radiation passed when copper with a thickness of 1.0 mm was used. The average MGV for copper groups was 70, which was lower than other metal groups. The minimum MGV was 63.22 for 1.0 mm copper. The maximum MGV appeared for PSPs having no metal that was equal to 129.57.

The results of the ANOVA test the experimental groups are given in Table 2. The table indicates that the groups have significantly different means (p<0.001). To find out which groups significantly differed from others, the comparison of the means was made using Tukey’s test. The results of Tukey's test are presented in Table 3. The table indicates that, in the comparison between the images of the second PSP, MGV of the non-metallic group was significantly different from all other groups containing metals (p<0.001). The groups for aluminum having different thicknesses were not significantly different from each other (p=0.067), but they were significantly different from the other groups. Lead and stainless steel with 0.5mm thickness were not significantly different (p =0.852), but they were significantly different from other groups. The 0.75mm stainless steel group was significantly different from all other groups (p<0.001). The 1 mm stainless steel group, copper 0.5 mm and copper 0.75mm were not significantly different from each other (p =0.307), but they were significantly different from other groups. The 1 mm copper group was significantly different from all other groups (p<0.001). (Table 3).

| Source | Degrees of Freedom | Sum of Squares | MS | F value | p value |

|---|---|---|---|---|---|

| Groups | 10 | 42962.4 | 4296.2 | 52.15 | 0.000 |

| Error | 139 | 11450.2 | 82.4 | - | - |

| Total | 149 | 54412.6 | - | - | - |

4. DISCUSSION

Features such as a higher dynamic range and greater sensitivity of digital sensors can reduce the amount of radiation to which patients are exposed. This perception was the main reason for the recent move from conventional to digital radiography in dentistry [13]. Digital systems apply lower doses compared to conventional radiography and use no protective materials such as lead foil. Therefore, it is necessary to examine the radiation behind PSPs to confirm the need for protective materials in digital systems.

In this study, we used the mean gray value of the second PSP for evaluating the reduced radiation by placing metal sheets behind the PSP. Ten different groups of metals with different thickness and one group with no metals were used for this investigation. The mean gray value of the second images for each group were determined and compared. Based on the findings, the use of metal reduced the mean gray value and reduced the radiation absorption of the second PSP.

| PSP Second Group | Subsets (p = 0.05) | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| Cu 1mm | 66.88 | - | - | - | - | - |

| Cu 0.5mm | - | 72.97 | - | - | - | - |

| Cu 0.75mm | - | 74.43 | - | - | - | - |

| SS 1mm | - | 76.02 | - | - | - | - |

| SS 0.75mm | - | - | 84.46 | - | - | - |

| SS 0.5mm | - | - | - | 92.88 | - | - |

| Pb | - | - | - | 94.89 | - | - |

| Al 1mm | - | - | - | - | 109.73 | - |

| Al 0.5mm | - | - | - | - | 113.36 | - |

| Al 0.75 | - | - | - | - | 113.58 | - |

| No metal | - | - | - | - | - | 122.83 |

| sig | 1.000 | .307 | 1.000 | .852 | .067 | 1.000 |

There were no significant differences between the MGV of 1 mm aluminum, 0.5 mm aluminum and 0.75 mm aluminum, but they were significantly different from the other groups. There was no significant difference between a lead and stainless steel in 0.5 mm but these two groups were significantly different from other groups. In fact, the effect of 0.5 mm stainless steel in reducing radiation was similar to lead foil in E Speed Carestream Kodak Films (atomic number 82 and 0.1 mm thickness). The 0.75 mm steel was significantly different with all other groups. The 1 mm steel, 0.5 mm copper and 0.75 mm copper groups did not differ significantly from each other, but these three groups were significantly different from the other groups. The 1mm copper group was different from all other groups.

The most reduction of MGV was in the 1 mm copper group. As the atomic number of the metals, their thickness and the k-layer increased, the x-ray absorption was also increased, and the MGV decreased, and the image was darker. The histogram of gray value of the images in the PSP in the metal-free group was generally uniform with gray peaks locating in the middle region, but in the second images of the other groups, with increasing atomic number and metal thickness, amount of MGV decreased and the distribution of dark gray shades increased. In the second image, the peak mean gray moved to the right indicating darker images.

The causes of darkening of the second PSP image were:

- Some are initial X-rays photons pass through the phantom tooth and cause the image.

- Scattered X-ray from the metal [14].

- The energy released from excited electrons on the surface of the metal due to the absorbing radiation received by the digital sensor.

- The preprocessing of the device. Because even in suboptimal exposure, digital images are rarely very clear. The image preprocessing process usually involves automatic data leveling [15]. Therefore, in this method, using the mean gray shade, it was concluded that increase in atomic number and increase in the thickness of the metal sheet, the second PSP image became darker.

Nejaim et al. [16] using a thermo-luminescent dosimeter reported on the effect of lead foil in a full mouths digital intra-oral radiography for reducing various organ doses. Consequently, lead foil reduced the doses to approximately 32% in the PSP system. Although the two study results cannot be directly compared, this study results support their findings for shielding effects by lead foil in the PSP system.

In a study by Nagasaka et al. [17], tungsten sheets it was indicated that this sheet adequately shielded the back radiation of the PSP. They reported that the doses beind the PSP without protective material were no different from behind a conventional film with lead foil. This result indicates that the PSP itself has the effect of reducing the equivalent of using a film with lead foil. In addition, the doses behind the PSP were more reduced by lead foil and tungsten sheets and this was significantly different in all areas compared to non-shielded PSPs. They concluded that tungsten sheets as an alternative shielding agent that could significantly reduce the radiation dose behind PSP. However, tungsten is a relatively high cost metal, but the sheets can be used several times. In our study, we used metals that are readily available, less expensive, and are available in different thicknesses. In addition, all of these sheets can be autoclaved, sterilized without alteration, and increases the rigidity of the PSP for bending in a mouth. ISO recommends that the thickness of a film package be less than 2 mm. Although the PSP package with metal sheets did not exceed this recommended value, patient inconvenience should be assessed.

CONCLUSION

The results of this study based on mean gray values of the images behind metal sheets indicated that:

1. The addition of lead and other metal sheets to PSP significantly reduced the amount of radiation.

2. Radiation reduction was decreased by an increase in atomic number and thickness of the metals.

3. Copper with 1.0 mm thickness resulted in the lowest radiation reduction.

ETHICS APPROVAL AND CONSENT TO PARTICIPATE

This study was approved by the Ethics Committee of Isfahan University of Medical Sciences, Iran. (IR.MUI.RESEARCH.REC.1398.696).

HUMAN AND ANIMAL RIGHTS

No Animals were used in this research. All human research procedures were followed in accordance with the ethical standards of the committee responsible for human experimentation (institutional and national), and with the Helsinki Declaration of 1975, as revised in 2013.

CONSENT FOR PUBLICATION

Not applicable.

AVAILABILITY OF DATA AND MATERIALS

The data that support the findings of this study are available from the corresponding author, [F.G.M], upon reasonable request.

FUNDING

This project was supported by Isfahan University of Medical Sciences, Isfahan, Iran.

CONFLICT OF INTEREST

The authors declare no conflict of interest, financial, or otherwise.

ACKNOWLEDGEMENTS

Declared none.